Verturn II VDM 2300 CNC

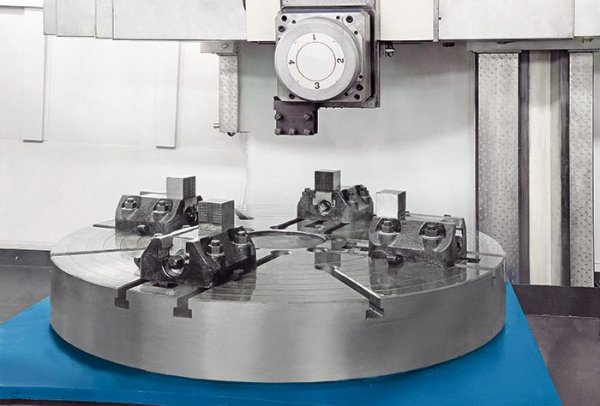

This series combines the proven virtues of the VDL vertical lathes with the latest CNC technology. Workpieces with large diameters and heavy weight can be loaded and unloaded safely and quickly. In addition, the Sinumerik 828D control is an absolute powerhouse. The automatic 4-station tool changer guarantees stability and the large 4-jaw face plate chuck securely holds large workpiece diameters. A heat exchanger in the control cabinet and the hydraulic unit with oil cooler ensure thermal balance. A chip conveyor rounds out the equipment package.

- Siemens 828 D Control

- Long boom for inside machining

- High drive power and a wide speed range

- 4-jaw independent chuck with large diameter

- Automatic 4-station tool changer