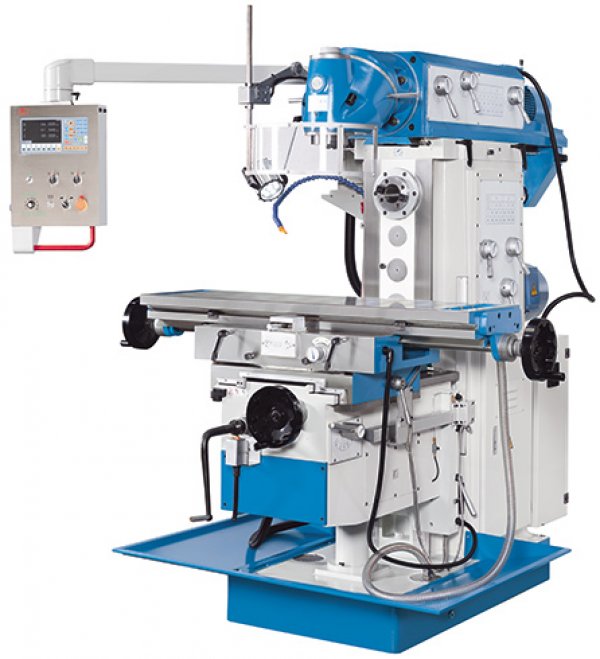

UWF 5

This universal milling machine is one of the top models of the UWF series, which is characterized by a large work area, universal milling head and horizontal spindle. The more powerful drive, the increased speed range and the infinitely variable servomotor feed extend the application range of the UWF 5. Your milling head can be swiveled on two planes and the horizontal spindle has its own drive with a finely graduated gear shift. With its extensive equipment, this model is perfect for repair shops as well as training and production departments.

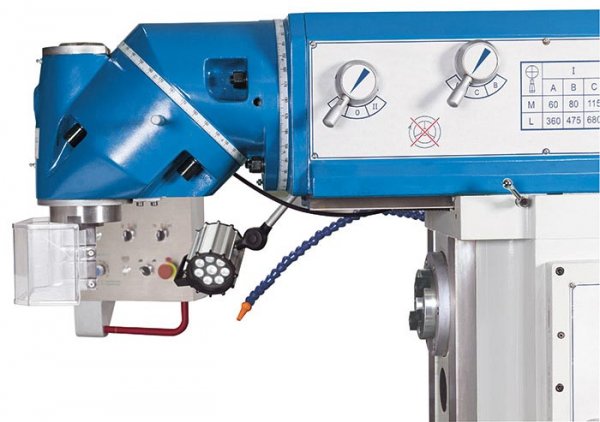

- Universal cutter head swivels on 2 levels

- Horizontal milling spindle with its own drive

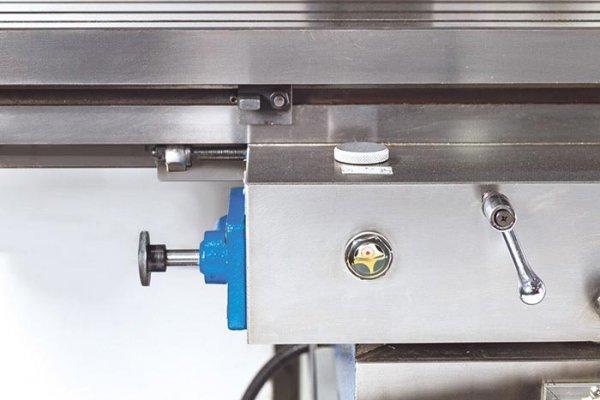

- Swiveling milling table

- Servo-feed on all axes with rapid feed

- Extensive standard equipment