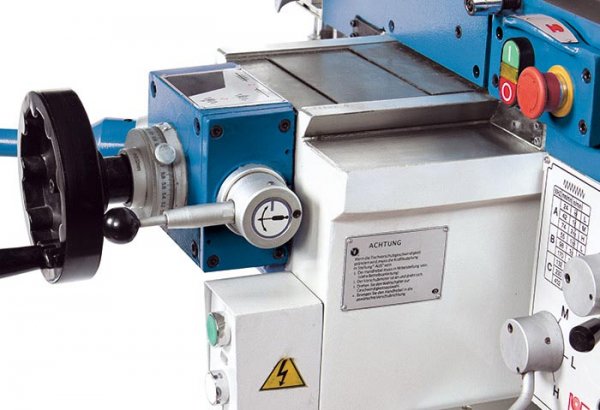

UWF 1.1

The milling machine is equipped with a large clamping table and a swiveling universal milling head that can be swiveled in two planes and also positioned horizontally. The UWF series thus almost covers the area of application of a universal milling machine. An automatic feed that can be switched via a gearbox drives the X- and Y-axes. The Z-axis can be traversed in rapid traverse. Dovetail guides in all axes can be precisely adjusted. With its extensive equipment, the UWF 1.1 is ideal for individual production, repair and training workshops.

- Universal cutter head swivels on 2 levels

- Horizontal milling spindle with its own drive

- Feed on X-axis and Y-axis

- Extensive standard equipment