| Working Area |

| Table set up area |

54 in x 12 in |

| Table load capacity (max.) |

770 lbs |

| Travels |

| Travel X-axis |

26.8 in |

| Travel Y-axis |

14 in |

| Travel Z-axis |

15 in |

| Vertical Milling Head |

| Spindle mount |

ISO 40 |

| Quill stroke |

5 in |

| Spindle nose-to-table surface distance |

7 in - 22 in |

| Speed range (infinitely variable, back gear ranges) |

50 rpm - 4.000 rpm |

| Rapid Feed |

| Rapid feed X-axis |

196.85 in/min |

| Rapid feed Y-axis |

118.11 in/min |

| Rapid feed Z-axis |

78.74 in/min |

| Feed |

| Feed speed (infinitely variable) |

0 in/min - 39 in/min |

| Feed per spindle revolution |

0 in/R - 0.04 in/R |

| Drive Capacity |

| Motor rating main drive |

5 Hp |

| Measures and Weights |

| Overall dimensions (length x width x height) |

100 in x 86 in x 89 in |

| Weight |

3.960 lbs |

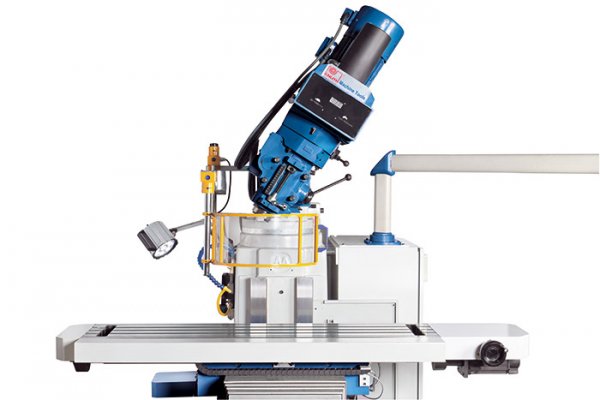

Conventional milling, now easier, more precise and more efficient due to integrated electronics

- The Servomill represents a new generation of advanced milling machines that are operated like a conventional machine

- This machine features a user-friendly design, significantly higher precision and increased machining capacity

- Very high reliability and long service life of all components ensure drastically reduced maintenance and increased reliability

- Rigid machine base in a proven design, and meticulous workmanship

- Variability via swiveling and moving top beam

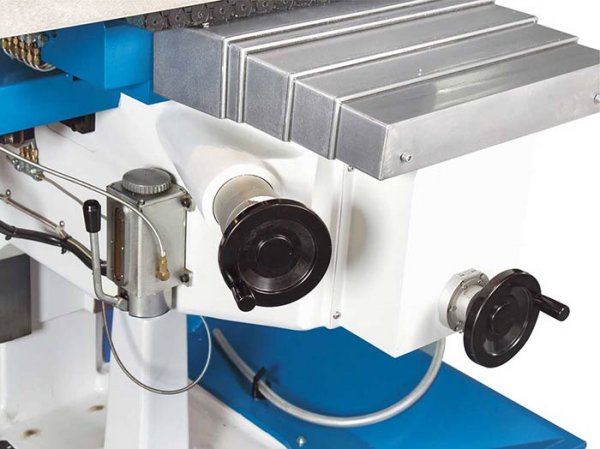

- Perfectly adjustable dovetail guide on the X-axis, and wide square guides in Y and Z direction

- High-precision preloaded ball screws on all 3 axes

- All guides are hardened and ground, and are supplied with oil by the central lubrication unit

- Cutter head swivels with pneumatic tool clamping and powerful 5 HP motor

- Infinitely variable spindle speed with back gearing and LED speed indicator

- Manual quill feed with micrometer depth stop allows for precise angular bores

- Large, swiveling control panel with integrated position indicator

Servomill - Highlights

- Control developed and built in Germany

- Positioning control for traveling pre-selected paths on all axes

- Constant cutting speed, where the feed speed is based on spindle speed

- Zero-backlash preloaded ball screws

- Servo motors on all axes, infinitely variable feed, rapid feed, and speed control

- Electronic spindle load indicator

- Electronic hand-wheels on all axes

- X, Y and Z axes can be controlled via joystick

- Integrated position indicator with glass scale

Your Advantages:

- Easy to use: intuitive operation - practical layout of control elements and streamlined function

- Automatic feed on all axes and infinitely variable rapid feed

- With speeds up to 197 in/min

- Set limit stops on any axis with the push of a button - 3 stop positions per axis can be stored

- More precise: operated via electronic hand-wheels - axes are powered by high-quality servo drives that translate your hand movements with the precision and dynamics of modern CNC machines

- More reliable: drives, spindles, and measuring systems are totally enclosed or mounted in protective enclosures and virtually maintenance-free

- Electronics - made in Germany

- More capacity: this machine only uses premium drive components that are designed for continuous operation

- Maintenance-free: no regular maintenance needed for the entire feed drive

- Advanced Feed Technology:

- Axes are powered by high-quality servo drives that translate your hand movements with the precision and dynamics of modern CNC machines

- Reliable, maintenance-free mass production technology

- High rapid feed rate for reduced machine down-times

- Ball screw drive on all axes:

- Considerably less errors due to loseness (backlash), resulting in significantly higher precision

- Significantly reduced friction, no stick-slip effect, reduced heat buildup, minimal wear

- Electronic hand-wheels:

- Micro-control via electronic hand-wheels offering the same handling and postioning as with a conventional machine, just smoother and more precise

- Joystick control:

- Maximum operator comfort for axis movements

- Easy handling during sequential processing

- Electronically controlled fixed stops:

- Set 2 limit stops at 3 positions on each axis by the push of a button - these buttons are grouped around the feed switch for intuitive control

- This ensures high repeatability during coordinate drilling or pocket cutting, and siginificantly more positions can be set up than on conventional machines

- Constant cutting speed:

- The feed rate is infinitely variable and can be coupled with the spindle speed in a selectable feed-per-spindle revolution ratio in the range of 0.0004 to 0.04 inch/rev

- This ensures a constant feed-per-tooth value and simplifies the operator's task of optimizing the machining operation

- Electronic spindle load indicator:

- Assists the operator in the most efficient utilization of machine and tool capacities

- Reliable indicator helps avoid damages caused by overloads

X.pos Plus - You will gain productivity,

quality and comfort

- Default coordinates

- Hole circle pattern calculation

- Vibration filter feature

- Mm/inch conversion

- 8 display languages

- Calculator function

- High-resolution display with excellent legibility

- State-of-the art electronics and a very robust, completely sealed enclosure ensure maximum safety and optimum production conditions

- A major focus during the development and selection of electronic components was the achievement of maximum resistance against external interferences and maintaining low temperature levels

- Background colors of the display can be changed as required or desired

- The keyboard membrane is highly resistant and yet very comfortable to touch

- The display also provides a key to toggle between radius and diameter

- The axis position is maintained when the display is turned off

- Graphical support with residual path display and sketch drawing

- Linear and non-linear length correction is possible

- Easy mounting, easy electric connection, and maintenance-free operation

3-axis position indicator

electronic hand-wheels

pneumatic tool clamping

chip tray

LED work lamp

coolant system

central lubrication

horizontal guideway cover

operating tools

operator instructions

Coolant Concentrate 5 Ltr.

- Improved chip flow, longer tool service life and better cut profile

- For sawing, drilling, milling, turning of steel, cast-iron, stainless steel, non-ferrous and light metals

- Dilute with water 1:20

- 1 canister contains 5 Liter

Coolant Concentrate 5 Ltr.

SKU: 103184

Coolant Concentrate 5 Ltr.

- Improved chip flow, longer tool service life and better cut profile

- For sawing, drilling, milling, turning of steel, cast-iron, stainless steel, non-ferrous and light metals

- Dilute with water 1:20

- 1 canister contains 5 Liter

Pivoted Mounts LK 5

SKU: 103331

Pivoted Mounts LK 5

- Damper elements absorb shock and vibration

- Vibration-free machine operation

- Set screws allow for easy machine alignment

Universal Facing / Lathe Bore Head ADA / SK40

SKU: 103404

Universal Facing / Lathe Bore Head ADA / SK40

Can be used on drill presses, lathes, milling machines, etc.

- With self-actuated slide advance and automatic stop activation

- Automatic advance ensures constant tool feed

- Adjustable guides

- Adjustable stops

- Made of carbon-chromium-molybdenum steel

- All parts are hardened and precision-ground

- Guaranteed maximum accuracy

- Incl. reducing sleeves 0.16", 0.31", 0.47"

Adapter SK 40 / MT 2

SKU: 103720

Adapter SK 40 / MT 2

- For tools with Morse taper shank and ISO mount

- Hardened and ground

Adapter SK 40 / MT 3

SKU: 103730

Adapter SK 40 / MT 3

- For tools with Morse taper shank and ISO mount

- Hardened and ground

Adapter SK 40 / MT 4

SKU: 103740

Adapter SK 40 / MT 4

- For tools with Morse taper shank and ISO mount

- Replaceable and exactly centered connection between machine and tool

- For use in milling machines, machining centers, and drill units

- Taper shank, ground inside and outside

- Secure seat, high repeatability for tool changes

Reduction Sleeve SK 40 / SK 30

SKU: 103750

Reduction Sleeve SK 40 / SK 30

- Replaceable and exactly centered connection between machine and tool

- For use in milling machines, machining centers, and drill units

- Taper shank, ground inside and outside

- Secure seat, high repeatability for tool changes

Shell End Milling Arbor Ø16 SK 40

SKU: 103895

Shell End Milling Arbor Ø16 SK 40

- For cutters with cross or longitudinal slot

- Including parallel key, driver ring, cutter tightening screw, special wrench

- Thread: M16

Shell End Milling Arbor Ø22 SK 40

SKU: 103900

Shell End Milling Arbor Ø22 SK 40

- For cutters with cross or longitudinal slot

- Including parallel key, driver ring, cutter tightening screw, special wrench

- Thread: M16

Shell End Milling Arbor Ø27 SK 40

SKU: 103905

Shell End Milling Arbor Ø27 SK 40

- For cutters with cross or longitudinal slot

- Including parallel key, driver ring, cutter tightening screw, special wrench

- Thread: M16

Shell End Milling Arbor Ø32 SK 40

SKU: 103910

Shell End Milling Arbor Ø32 SK 40

- For cutters with cross or longitudinal slot

- Including parallel key, driver ring, cutter tightening screw, special wrench

- Thread: M16

Shell End Milling Arbor Ø40 SK 40

SKU: 103915

Shell End Milling Arbor Ø40 SK 40

- For cutters with cross or longitudinal slot

- Including parallel key, driver ring, cutter tightening screw, special wrench

- Thread: M16

Accessory-Set ISO 40 5-pc.

SKU: 104596

Accessory-Set ISO 40 5-pc.

- Incl. keyless drill chuck and drill chuck arbors

- In wooden case

Content / Set:

- Reducing sleeve: ISO 40 / MT 2

- Reducing sleeve: ISO 40 /MT 3

- Reducing sleeve: ISO 40 / MT 4

- Tool holder bit: ISO 40 / B 18

- Keyless drill chuck: 0.12"-0.63" / B 18

Keyless Drill Chuck 0.04-0.5 in B 16

SKU: 104765

Keyless Drill Chuck 0.04-0.5 in B 16

- Chucking range 0.039"-0.51"

- Mount B 16

Keyless Drill Chuck 0.12-0.63 in B 18

SKU: 104770

Keyless Drill Chuck 0.12-0.63 in B 18

- Chucking range 0.12"-0.63"

- Mount B 18

Drill Chuck Arbors ISO 40 / B 16

SKU: 104780

Drill Chuck Arbors ISO 40 / B 16

- Hardened and ground for optimum concentricity

- High-precision design for mounting of drill chucks on milling machines, machining centers, equipment, etc.

Drill Chuck Arbors ISO 40 / B 18

SKU: 104781

Drill Chuck Arbors ISO 40 / B 18

- Hardened and ground for optimum concentricity

- High-precision design for mounting of drill chucks on milling machines, machining centers, equipment, etc.

Machine vise with pull-down system NZM 125

SKU: 104918

Machine vise with pull-down system NZM 125

- Pull-down system: absolutely secure work piece hold even during cutting of heavy parts

- Hardened and precision-ground steel jaws

- Dial turns 360° and has 1° scale division

- Parallelism ± 0,03 mm / 100 mm

- Precise, hardened jaw guides

- Made of high-quality cast-iron

MS 125 Machine Vise

SKU: 104955

MS 125 Machine Vise

- High quality cast iron

- Hardened and ground replaceable steel jaws

- Covered spindle

- Forged bronze spindle nut

- Including hand crank, swivel-base and scale

Deluxe Clamping Tool Set 16/M14

SKU: 105300

Deluxe Clamping Tool Set 16/M14

- 52 parts

- In a convenient, sturdy steel magazine

- 24 stud bolts, 4 each in the lengths 3", 4", 5", 6", 7", 8"

- 4 extension nuts, 6 stepped clamps (3 pair), 6 T-slot nuts, 6 hexagon nuts flanged, step blocks (3 pairs)

Step of Step Blocks

SKU: 105340

Step of Step Blocks

- 20 each (10 pairs) in wooden box

- Black-finished steel

Stud Bolt Set, and T-Slot Nuts 16/M14

SKU: 105360

Stud Bolt Set, and T-Slot Nuts 16/M14

- 38 parts

- 24 stud bolts, 4 each in the lengths 3", 4", 5", 6", 7", 8"

- 6 T-slot nuts

- 4 extension nuts

- Hexagon nuts flanged

Swivel Hold-Down Clamp Set 100/M14

SKU: 105795

Swivel Hold-Down Clamp Set 100/M14

- High quality steel, black-finished

- Available in pairs only

ER 32 Collet Set 6 pcs.

SKU: 106052

ER 32 Collet Set 6 pcs.

- 6 pcs: 0.24", 0.31", 0.4", 0.47", 0.6", 0.8"

ER 40 Collet Set 15 pcs.

SKU: 106075

ER 40 Collet Set 15 pcs.

- 6 pcs: 0.24", 0.31", 0.4", 0.47", 0.6", 0.8"

ER 32 Collet Chuck / Mount ISO 40

SKU: 106056

ER 32 Collet Chuck / Mount ISO 40

- For clamping tools with cylindrical shank in ER collets according to DIN 6499

ER 40 Collet Chuck / Mount ISO 40

SKU: 106062

ER 40 Collet Chuck / Mount ISO 40

- For clamping tools with cylindrical shank in ER collets according to DIN 6499

Milling Chuck WELDON ISO 40 / Ø 0.24 in

SKU: 106801

Milling Chuck WELDON ISO 40 / Ø 0.24 in

- For tools with cylindrical shank and setup area in accordance with DIN 1835 B

- Forged, case-hardened, precision-ground

Milling Chuck WELDON ISO 40 / Ø 0.3 in

SKU: 106802

Milling Chuck WELDON ISO 40 / Ø 0.3 in

- For tools with cylindrical shank and setup area in accordance with DIN 1835 B

- Forged, case-hardened, precision-ground

Milling Chuck WELDON ISO 40 / Ø 0.4 in

SKU: 106803

Milling Chuck WELDON ISO 40 / Ø 0.4 in

- For tools with cylindrical shank and setup area in accordance with DIN 1835 B

- Forged, case-hardened, precision-ground

Milling Chuck WELDON ISO 40 / Ø 0.47 in

SKU: 106804

Milling Chuck WELDON ISO 40 / Ø 0.47 in

- For tools with cylindrical shank and setup area in accordance with DIN 1835 B

- Forged, case-hardened, precision-ground

Milling Chuck WELDON ISO 40 / Ø 0.63 in

SKU: 106805

Milling Chuck WELDON ISO 40 / Ø 0.63 in

- For tools with cylindrical shank and setup area in accordance with DIN 1835 B

- Forged, case-hardened, precision-ground

Milling Chuck WELDON ISO 40 / Ø 0.78 in

SKU: 106806

Milling Chuck WELDON ISO 40 / Ø 0.78 in

- For tools with cylindrical shank and setup area in accordance with DIN 1835 B

- Forged, case-hardened, precision-ground

Milling Chuck WELDON ISO 40 / Ø 1 in

SKU: 106807

Milling Chuck WELDON ISO 40 / Ø 1 in

- For tools with cylindrical shank and setup area in accordance with DIN 1835 B

- Forged, case-hardened, precision-ground

Milling Chuck WELDON ISO 40 / Ø 1.26 in

SKU: 106808

Milling Chuck WELDON ISO 40 / Ø 1.26 in

- For tools with cylindrical shank and setup area in accordance with DIN 1835 B

- Forged, case-hardened, precision-ground

Indexable Insert End Mills Set 0.98 in

SKU: 107800

Indexable Insert End Mills Set 0.98 in

- Shaft 0.75", Weldon shaft with torque surface

- With carbide tips, quality P20

Roughing End Mill Cutter 40

SKU: 108400

Roughing End Mill Cutter 40

- With cross groove

- Right-hand cut with right-hand spiral

- HSS-E, hardness HRC 68

- Roughing cut teeth

Roughing End Mill Cutter 50

SKU: 108401

Roughing End Mill Cutter 50

- With cross groove

- Right-hand cut with right-hand spiral

- HSS-E, hardness HRC 68

- Roughing cut teeth

Roughing End Mill Cutter 63

SKU: 108402

Roughing End Mill Cutter 63

- With cross groove

- Right-hand cut with right-hand spiral

- HSS-E, hardness HRC 68

- Roughing cut teeth

Roughing End Mill Cutter 80

SKU: 108403

Roughing End Mill Cutter 80

- With cross groove

- Right-hand cut with right-hand spiral

- HSS-E, hardness HRC 68

- Roughing cut teeth

Roughing Shank Cutter 10 pcs.

SKU: 108445

Roughing Shank Cutter 10 pcs.

Set = 10 pieces

- DIN 844 B, DIN 1835 B, Weldon shaft

- HSS, ionized and therefore HRC 68

- Right-hand cut

- For materials up to 1000 N/mm2 strength

- Diameter: 6, 8, 10, 12, 14, 16, 18, 20, 22, 25 mm

Lathe Bore Head with Boring Bar Set 2 in 9 pcs.

SKU: 108631

Lathe Bore Head with Boring Bar Set 2 in 9 pcs.

- For easy inside diameter turning on drill presses, lathes and milling machines

- Micrometer screw for precise inside turning diameter adjustment

- High quality steel hardened and precision-ground

- Feed: 0.0004" / division line

- 2 vertical tool mounts, 1 horizontal tool mount

Lathe Bore Head with Boring Bar Set 3 in 12 pcs.

SKU: 108633

Lathe Bore Head with Boring Bar Set 3 in 12 pcs.

- For easy inside diameter turning on drill presses, lathes and milling machines

- Micrometer screw for precise inside turning diameter adjustment

- High quality steel hardened and precision-ground

- Feed: 0.0004" / division line

- 2 vertical tool mounts, 1 horizontal tool mount

Mounting Shaft ISO 40

SKU: 108637

Mounting Shaft ISO 40

- Mount with connection thread for reaming heads

- With draw-in bolt thread for use on milling machines

- Tapers are hardened and ground

- The reaming head set is provided without mount

- Shank with draw-in thread ISO 40

Dividing head HT

SKU: 110953

Dividing head HT

- For direct and indirect divisions

- Spindle runs in precision tapered roller bearings

- Phosphorous/bronze worm gear with hardened and ground CrNi steel worm

- Disengage gears for direct divisions

- Gear ratio 40:1

- Swivels from 10° below horizontal to vertical (-10° to 90°)

- Every division for 2 to 50 parts and many divisions up to 380 parts

Divider ST 130

SKU: 110960

Divider ST 130

- Gear ratio 1:90, disengages for direct division, manual 360° rotation of chuck

- Hand wheel with scale ring

- Nonius division 10''

- 6 masks for direct division of 2, 3, 4, 6, 8, 12, 24 parts

- Hardened and ground teeth with 3-jaw chuck, 6.5" or 7.75"

Optional Accessory Set / ST 130

SKU: 110970

Optional Accessory Set / ST 130

Applications:

Workpieces can be clamped between the divider and the tailstock for a horizontal workpiece alignment.

Upgrade to a Universal Divider

Dividing plate set for indirect dividing:

- The spindle is positioned via dividing plates that have several concentric hole pattern

- Using so-called shears (two pointers rotating around the crank shaft) simplifies positioning through several crank rotations, since counting between holes on the divider plate is not necessary

- The user only has to count the number of full rotations

- Benefit: Many divisions can be performed with only a few divider plates,

higher accuracy is achieved by using a reduction worm gear, which causes a high-resolution continued rotation of the crank

PMS 100

SKU: 125012

PMS 100

- Swivels on 2 axis

- High precision vise for accurate and exact precision mechanics work (also suitable for watch making, jewellery industries)

- Swivels from horizontal (180°) to vertical (90°)

- Turns 360° on a dial

- Jaws are made of hardened and precision-ground tool steel

HS 125 Hydraulic Machine Vise

SKU: 125024

HS 125 Hydraulic Machine Vise

- Hardened and precision-ground jaws and body

- High precision and wear-resistant material ensure long service-life

- Clamping pressure is up to ten times as high as with conventional machine vises

- Swivel-base mounted vise body, 360° swivel

- Constant clamping pressure, unaffected by vibration and shock

- Hydraulic power booster

INDEX-feature / RT 160-320

SKU: 125805

INDEX-feature / RT 160-320

- For direct and indirect division

- From 2 to 66, all divisions from 68 to 132 dividable by 2, 3 a. 5 can be performed

Tailstock / RT 200/250

SKU: 125820

Tailstock / RT 200/250

Rotary Table RT 200

SKU: 125835

Rotary Table RT 200

- Completely enclosed design, prevents contamination from dirt and chips

- Setup table rotates on a large ring-shaped box way

- The very effective clamp pulls the setup table down straight, without any change of position or radial pressure and presses it against the guide way

- For quick manual turning, the worm can be disengaged from the worm gear by pushing down the hand-lever

- Setup table with 360° scale

- The zero-backlash of worm and worm gear is adjustable

- Hand wheel scale gradation 10''

- Hand wheel can be replaced with indexing plate

- With 4 radial setup T-slots (0.5")

- Very low profile

- Guide slot in the vertical base plane

- Can be used vertically

Accuracy (max. deviation):

- Surface concentricity of work table setup surface 300 : 0.0006"

- Concentricity of setup < = 0.0006"

- Parallelism of setup to base surface 300 : 0.02

- Concentricity of setup table taper bore < = 0.0004"

- Parallelism of bore axis to vertical setup surface 0.0012"

- Parallelism of bore axis to slot in the vertical setup surface 0.02

- Parallelism between vertical setup area and conus taper connection axis - tailstock center 0.02

- Parallelism between slot in the vertical setup surface and the connecting axis between centers 0.02

- Division accuracy 45'"

Corrugated Parallel Parts 0.4-0.9 in

SKU: 128960

Corrugated Parallel Parts 0.4-0.9 in

- Saves time when clamping parts for grinding, milling, drilling etc.

- No chips are left on the supporting surface to ensure unaffected parallelism of the clamped work piece

- Multiple flat parts, or individual thin parts can be clamped

- Hardened and tempered spring steel, 4.33" long parallelism ± 0.005 mm, precision-ground

- 8 pair per set - 0,07" incrementing

Corrugated Parallels 1-1.5 in

SKU: 128961

Corrugated Parallels 1-1.5 in

- Saves time when clamping parts for grinding, milling, drilling etc.

- No chips are left on the supporting surface to ensure unaffected parallelism of the clamped work piece

- Multiple flat parts, or individual thin parts can be clamped

- Hardened and tempered spring steel, 4.33" long parallelism ± 0.005 mm, precision-ground

- 8 pair per set - 0,07" incrementing