R 100

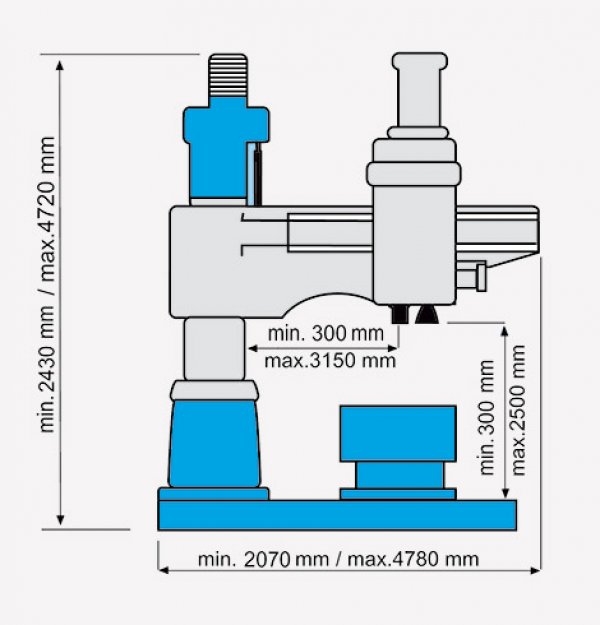

The top model of our radial drilling machines offers 100 mm (3.9 in) drilling capacity and a huge work area. The stability required for this is achieved through the very heavy design and XL dimensions of all components. Due to the easy handling of large and heavy workpieces and the considerable flexibility due to the long arm, these models are recommended for shipyards, steel and heavy industry. The R-series has a hydraulically switched gearbox and a multi-plate reversing clutch. Despite the size, it is easy to transport and assembly takes place on site.

- Heavy duty and high performance

- Standard cube table for extended application possibilities

- Robust construction for constant high accuracy

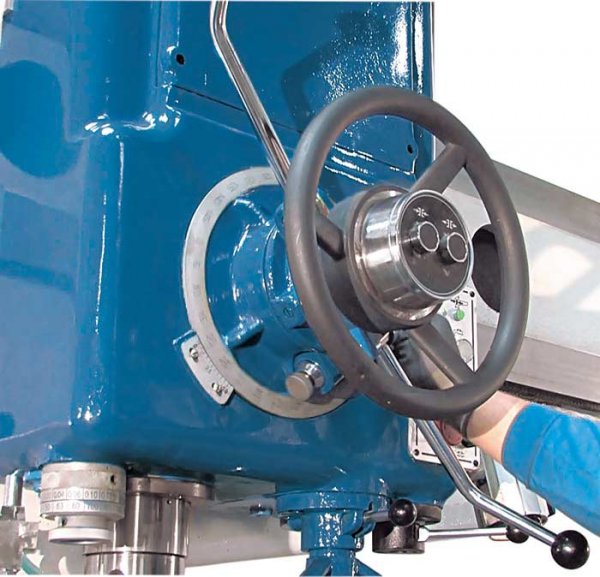

- Motorized moveable headstock for easy and comfortable operation