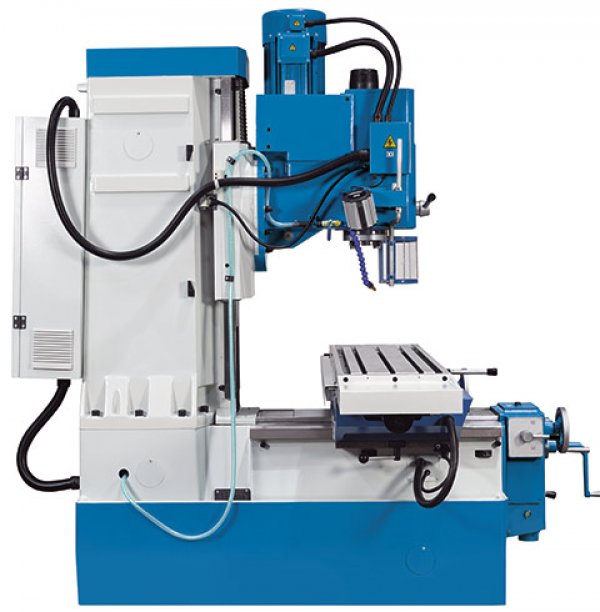

KB 1400

The heavy universal bed milling machine offers wide guides and high drive power for superior cutting performance, and with its extensive equipment is ideally suited for plant and machine construction. The heavy vertical milling head can be swiveled to the right and left, the quill can be moved manually, and the spindle speed can be continuously adjusted. The feed in the Y- and X-axes can be varied using a robust gearbox. All axes have rapid traverse and the large clamping table offers plenty of space for workpieces and clamping devices.

- Large work area

- Swiveling vertical cutter head

- Infinitely variable feed

- Extensive standard equipment