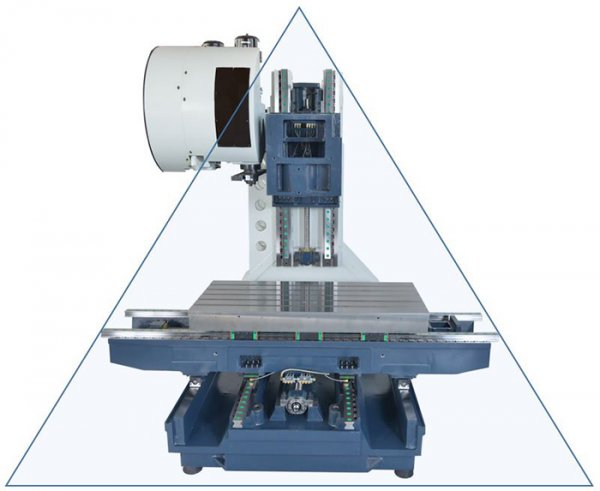

X.mill 5X 1000 HDH CNC Machining Center

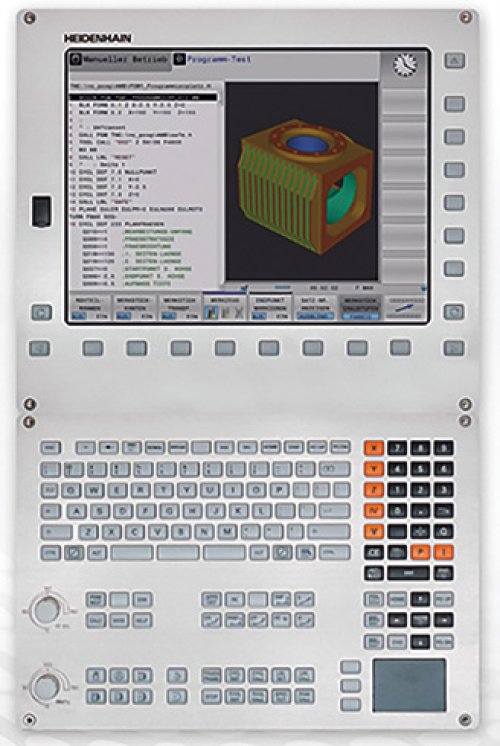

The X.mill 5X series is the ideal, cost-effective solution for multi-sided machining. For the CNC control you can choose between Heidenhain, Siemens or Fanuc controls and benefit from the outstanding price-performance ratio of this series. Based on the X.mill T series, the models are preconfigured as standard with a rotary swivel table for complex 3 + 2-axis milling applications. A wide range of accessories also enables adaptation to specific requirements.

- Optimized frame design using FEM analysis

- Extra wide Y-shaped column for increased rigidity

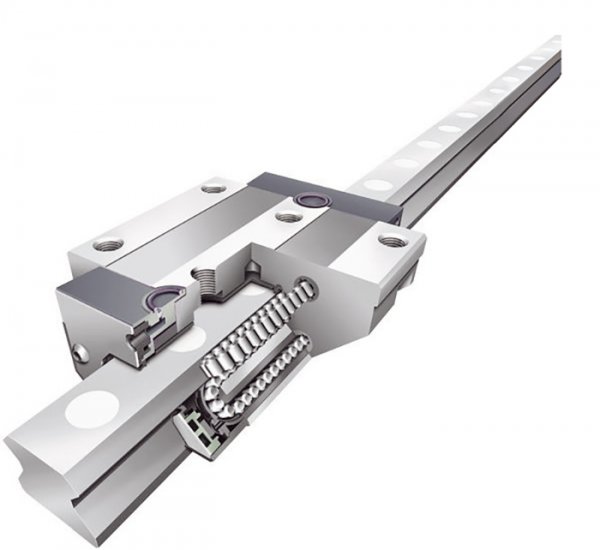

- Ø32 mm C3 preloaded ball screws for high accuracy

- 3+2 axes configuration for complex machining

- Available with Siemens, Fanuc or Heidenhain control

- High customization and automation possibilities