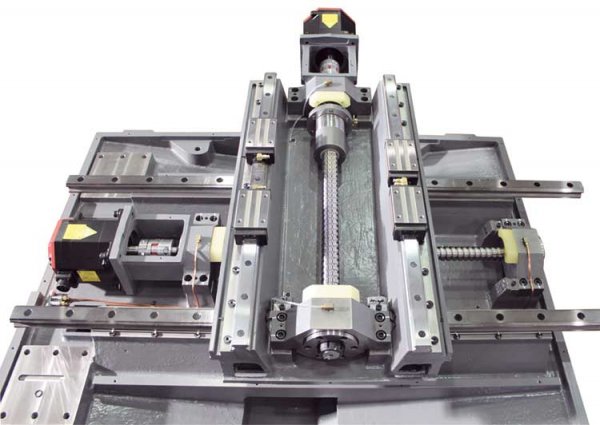

VECTOR 850 M SI (BT40)

The Vector series is the compact all-in-one machining solution, designed and preconfigured for complex manufacturing challenges. The machines are designed using the latest FEM analysis software. The production takes place under strict quality control in order to guarantee perfect execution. Both the tried and tested Meehanite cast and the delta construction of the column ensure additional stability of the machine frame. The consistently high-quality components guarantee smooth operation during multiple shifts.

- Optimized frame design using FEM analysis

- Extra wide Y-shaped meehanite column for max. rigidity

- 30-bar through-spindle coolant to ensure optimum machining quality

- Built for multi-shift production

- High customization and automation possibilities

- 2 years standard warranty