Top cover for X.Mill/Vector 650-1000

SKU: 252819

Top cover for X.Mill/Vector 650-1000

Renishaw OMP 40 workpiece measuring

SKU: 252820

Renishaw OMP 40 workpiece measuring

Connection for 4th axis (wiring only and axis chart)

SKU: 253019

Connection for 4th axis (wiring only and axis chart)

Renishaw TS27R tool measuring system

SKU: 253386

Renishaw TS27R tool measuring system

Renishaw OTS wireless tool setter (OTS)

SKU: 253598

Renishaw OTS wireless tool setter (OTS)

Spindle speed upgrade 10,000 to 12,000 rpm (belt type)

SKU: 253609

Spindle speed upgrade 10,000 to 12,000 rpm (belt type)

Prepared for Renishaw OMP40

SKU: 253613

Prepared for Renishaw OMP40

Manual tailstock ST-170T for rotary table

SKU: 253618

Manual tailstock ST-170T for rotary table

Manual tailstock ST-255T for rotary table

SKU: 253620

Manual tailstock ST-255T for rotary table

Manual chuck, 6'', for rotary table

SKU: 253622

Manual chuck, 6'', for rotary table

Manual chuck, 9'', for rotary table

SKU: 253624

Manual chuck, 9'', for rotary table

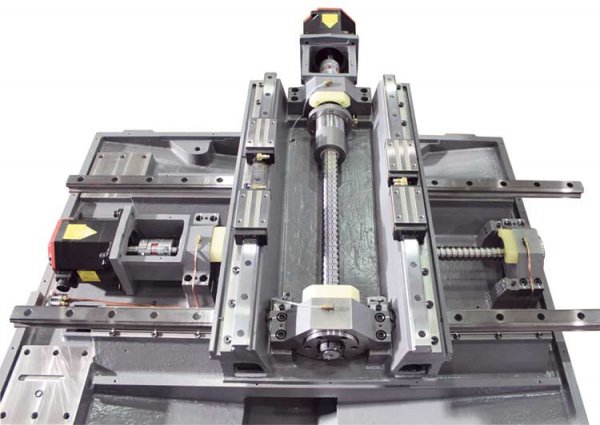

6.69" diam. 4th axis (4th axis, servo motor, driver, air brakes)(H)

SKU: 253644

6.69" diam. 4th axis (4th axis, servo motor, driver, air brakes)(H)

8.27" diam. 4th axis (4th axis, servo motor, driver, air brakes)(H)

SKU: 253645

8.27" diam. 4th axis (4th axis, servo motor, driver, air brakes)(H)

9.84" diam. 4th axis (4th axis, servo motor, driver, air brakes)(H)

SKU: 253646

9.84" diam. 4th axis (4th axis, servo motor, driver, air brakes)(H)

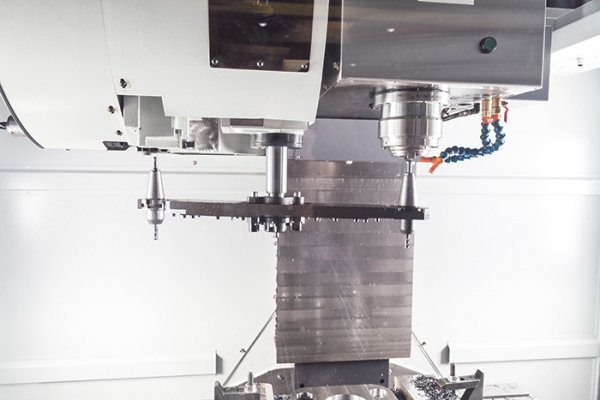

Renishaw OMP 60 workpiece measuring system (BT40)

SKU: 253681

Renishaw OMP 60 workpiece measuring system (BT40)

7.87" diam. 4th & 5th axis for Vector 650/850/1000 (HDH)

SKU: 253683

7.87" diam. 4th & 5th axis for Vector 650/850/1000 (HDH)

Air through spindle for Vector

SKU: 253782

Air through spindle for Vector

Spindle upgrade from ST40 to BBT40 for X.Mill/Vector 650-1000

SKU: 253951

Spindle upgrade from ST40 to BBT40 for X.Mill/Vector 650-1000

Draw bolt acc to DIN 69872A ST40 with bore

SKU: 253962

Draw bolt acc to DIN 69872A ST40 with bore

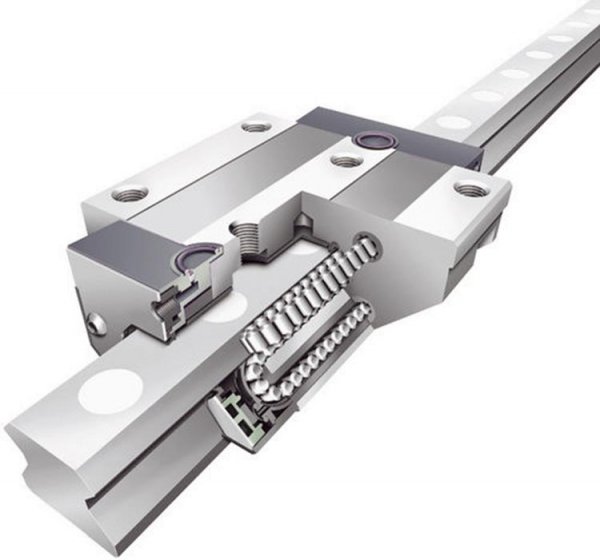

Reinforced machine base with 800 mm Z axis travel

SKU: 253625

Reinforced machine base with 800 mm Z axis travel