V-Turn 410/1500

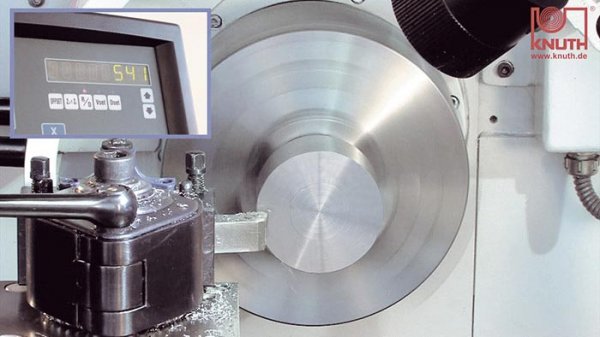

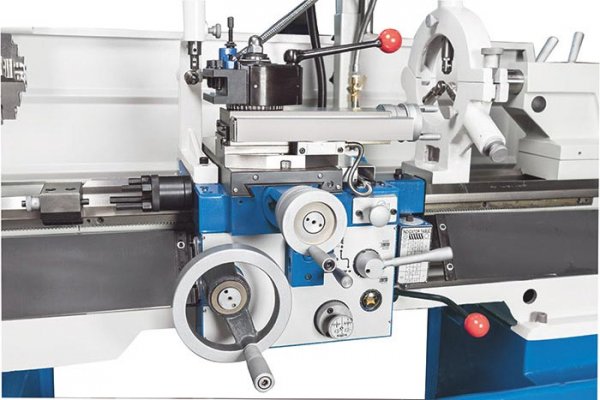

Our bestseller V-Turn is a precision lathe that is also suitable for production. Equipped with an inverter and a high-performance motor, it achieves spindle speeds of up to 3,000 1/min and processes workpieces with small diameters efficiently and of the best quality. The models also offer strength and stability for heavier machining. When facing, the "constant cutting speed" function integrated in the X-Pos adapts the spindle speed to the turning diameter and thus delivers quality that is comparable to the results of a CNC machine.

- Constant cutting speed

- High spindle speed and motor power

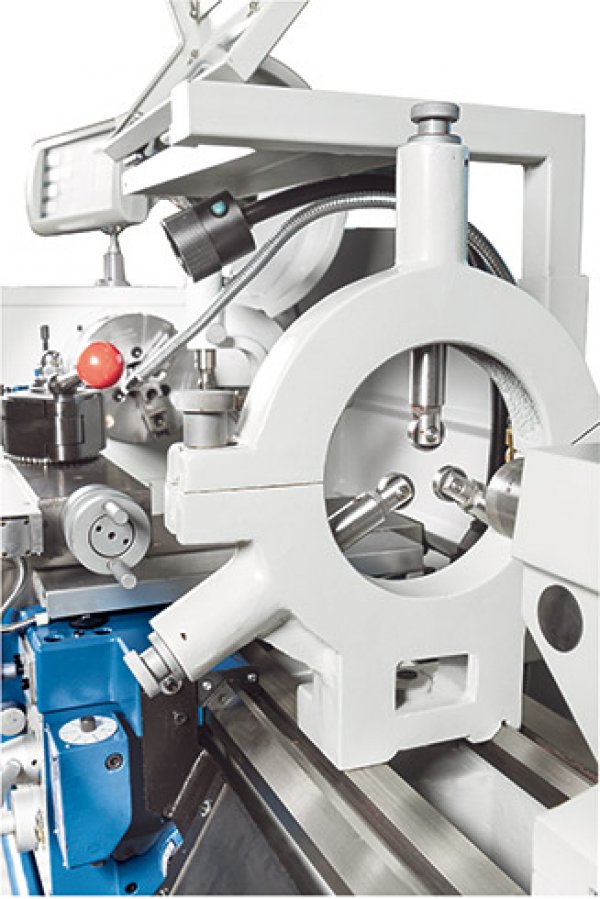

- Extensive standard equipment

- Wide range of applications