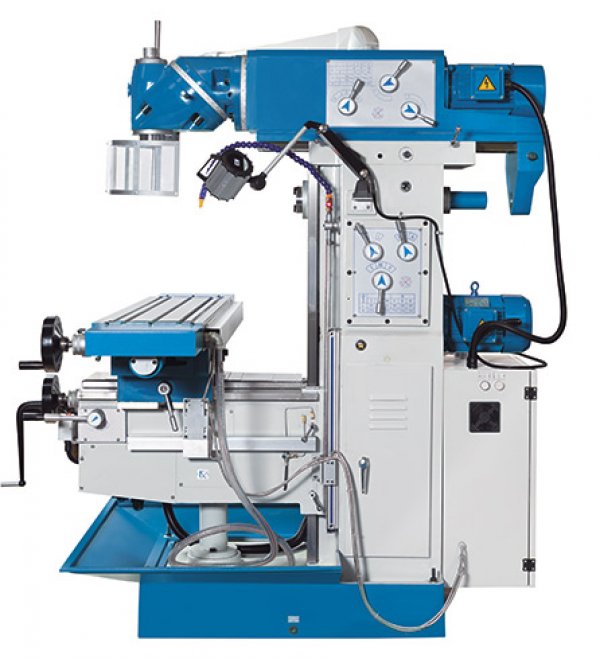

UWF 3.2

The versatile universal milling machine complements the tried and tested UWF 3. Both models have the large work area, the universal milling head and the horizontal spindle in common. The new UWF 3.2. however has a slightly higher speed range and an infinitely variable servomotor feed, which extends its range of application. Together with the extensive equipment, this model is also ideally suited for repair workshops as well as training and production departments.

- Universal cutter head swivels on 2 levels

- Outer arbor support for horizontal milling

- Swiveling milling table

- Servo-feed on all axes with rapid feed

- Extensive standard equipment