TubeTurn 200

The lathes of the TubeTurn series are designed to optimally machine tubes for the oil production and processing industry. The particularly large spindle bore and an additional chuck on the back of the main spindle, enable pipes to be securely clamped through the spindle bore. In this application, external steady rests can guide the workpieces outside the machine. The entire design of the machines is very robust and the standard taper turning device extends the range of applications of the series.

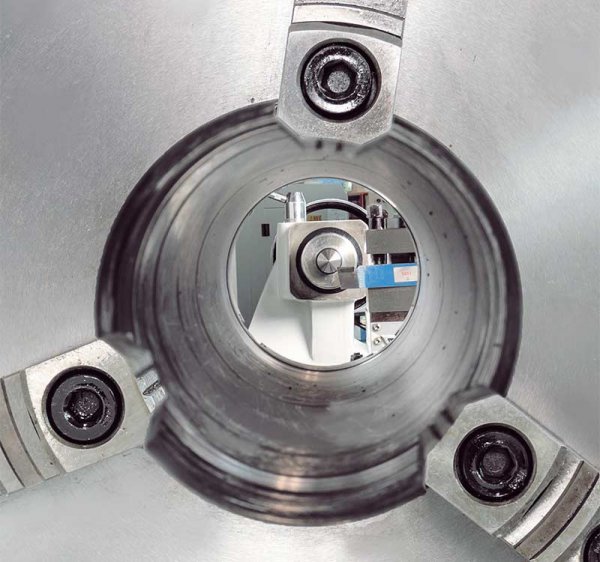

- Front and rear chuck

- Large spindle bore

- Taper turning feature

- Assembled 3-axis position indicator