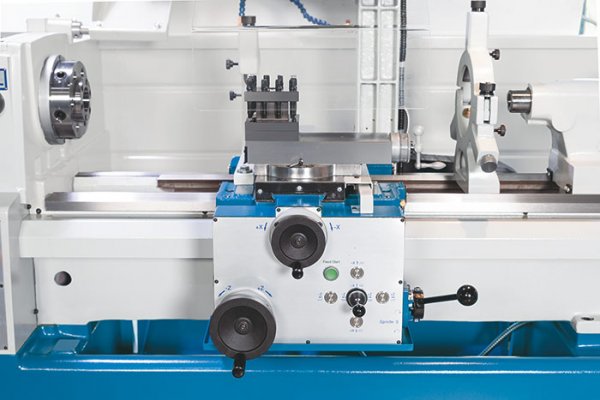

Servoturn® 410 NC

The Servoturn series of universal lathes combines the most modern feed technology with classic mechanical engineering. In contrast to standard conventional lathes, this series has ball screw drives and electronic hand wheels on all axes. High-torque servo motors implement every feed movement with the dynamics of modern CNC machines. Without gear change wheels and gears, feed and thread pitches can be selected electronically. Rapid traverses on all axes reduce non-productive time and electronic stops offer high repeat accuracy.

- Intuitive operation

- Servo drive for feed and tapping

- Turning of tapers and radii

- Clear touch screen

- Electronic handwheels