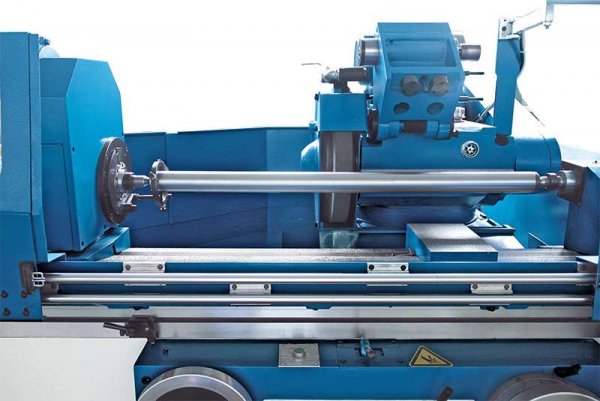

RSM 750 C

The models of the RSM C series are precision cylindrical grinding machines designed for long and heavier workpieces. The series is suitable for processing individual parts as well as for small series production and offer additional flexibility with the internal grinding device. The classic design with a large machine bed, ground guides, and powerful drives for the work spindle, grinding spindle and hydraulic unit, make these machines a cost-effective solution for the precision grinding of larger workpieces.

- Internal and external grinding

- Hydrostatic bearings for high surface quality

- Heavy machine frame to support large workpieces

- Swiveling headstock for conical grinding of short parts

- Integrated rapid feed on Z-axis with manual return

- Extensive package of standard accessories