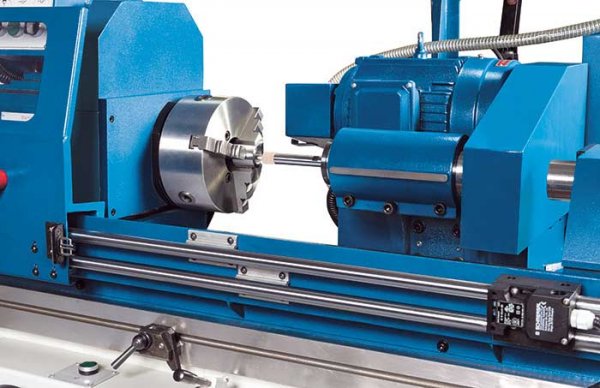

RSM 500 A

The machine frames of the RSM series are characterized by a heavy design and long, supporting guideways. The table can be swiveled and the finely adjustable hydraulic feed moves smoothly in the longitudinal direction. A large scale ring on the handwheel of the X-axis facilitates precise infeed and the zero stop guarantees compliance with the desired dimension. The standard position indicator with linear scales is used to check the actual values. The headstock is rotated 180 degrees for internal grinding. An extensive accessory package is standard.

- Internal and external grinding

- Hydrostatic bearings for high surface quality

- Swiveling headstock for conical grinding of short parts

- Integrated rapid feed on Z-axis with manual return

- Extensive package of standard accessories