Roturn 402 C

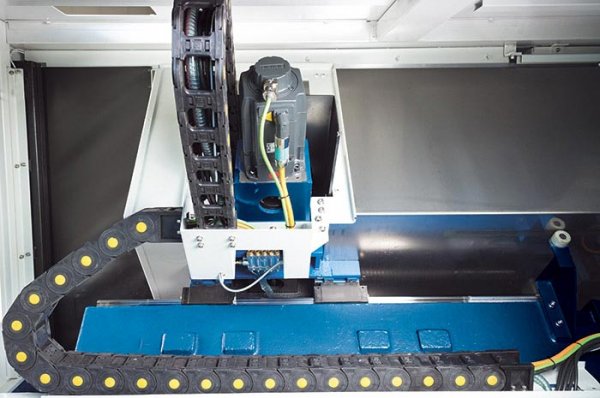

This machine of the ROTURN C series impresses with the classic virtues of a compact CNC production lathe. With its Siemens 828 D Basic control, it meets all the requirements for current control technology. The inclined bed machine with 8-station tool turret and powerful 15 kW (20 hp) main spindle motor has a hydraulic 3-jaw chuck with through-hole. The tailstock is equipped with a hydraulically operated quill and a large stroke. A flat top conveyor and a high-performance coolant system round out the standard equipment.

- Powerful main spindle motor

- 8 station tool turret

- Includes chip conveyor

- Siemens 828 control

- Chuck with through-hole