| Working Area |

| Number of T-slots |

6 positions |

| Table dimensions |

16 in x 31 in |

| Table load capacity (max.) |

440 lbs |

| T-slot (width x spacing) |

0.55 in x 2.48 in |

| Vertical table |

9 in x 40 in |

| T-slots, vertical table (number) |

3 positions |

| Travels |

| Travel X-axis |

19.7 in |

| Travel Y-axis |

16 in |

| Travel Z-axis |

16 in |

| Vertical Milling Spindle |

| Travel pinole |

2 in |

| Spindle center - column (min.) |

6 in |

| Spindle center - column (max.) |

26 in |

| Vertical Milling Head |

| Angular adjustment of vertical head |

± 90° |

| Rapid Feed |

| Rapid feed X-axis |

47.24 in/min |

| Rapid feed Y-axis |

47.24 in/min |

| Rapid feed Z-axis |

47.24 in/min |

| Feed |

| Work feed X-axis |

0.394 in/min - 39.37 in/min |

| Work feed Y-axis |

0.394 in/min - 39.37 in/min |

| Work feed Z-axis |

0.394 in/min - 39.37 in/min |

| Horizontal Milling Spindle / Vertical Milling Spindle |

| Speed range-stages |

2 |

| Speed range |

40 rpm - 2.000 rpm |

| Spindle mount |

ISO 40 |

| Drive Capacity |

| Motor rating main drive |

4.3 Hp |

| Motor rating coolant pump |

0.1 Hp |

| Measures and Weights |

| Overall dimensions (length x width x height) |

60 in x 67 in x 71 in |

| Weight |

3.410 lbs |

- The Machine column made of premium cast-iron, ensures maximum dynamic rigidity and constant precision

- Precise preloaded ball screws on all axes

- Ergonomically arranged controls and a swivelling control panel plus standard digital position indicator for maximum operator comfort

- Both machines feature rigid outer arbor supports for horizontal milling

- Large work tables and long travels of this compact machine allow a wide range of applications

- Automatic feed on all axes, infinitely variable, and with fast rapid feed

- The vertical cutter head swivels, and the quill can be moved manually

- The infinitely variable main spindle drive with counter gear offers a wide speed range with high torque

- Extensive accessory package included

- Central lubrication system is standard equipment

- The price includes a fully assembled 3-axis position indicator

electronic hand-wheels

3-axis position indicator

central lubrication

reducing sleeves MT1, MT2, MT3

collet chuck with collets 0.08,0.12,0.16,0.12,0.24,0.31,0.4,0.48 in

horizontal milling arbor 0.63 in

horizontal milling arbor 0.87 in

cutter arbor, long, 1.06 inch

horizontal milling arbor 1.26 in

Counterholder for horizontal milling

chip tray

coolant system

work lamp

pull rod (M16) for horizontal / vertical spindle

level pads and bolts

operating tools

operator manual

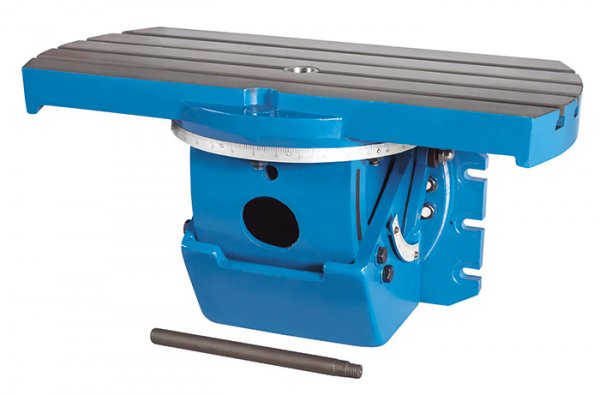

Universal swivel table for FPK 4.3 / FPK 6.3

Universal swivel table for FPK 4.3 / FPK 6.3

SKU: 253721

Universal swivel table for FPK 4.3 / FPK 6.3

Coolant Concentrate 5 Ltr.

SKU: 103184

Coolant Concentrate 5 Ltr.

- Improved chip flow, longer tool service life and better cut profile

- For sawing, drilling, milling, turning of steel, cast-iron, stainless steel, non-ferrous and light metals

- Dilute with water 1:20

- 1 canister contains 5 Liter

Shell End Milling Arbor Ø16 SK 40

SKU: 103895

Shell End Milling Arbor Ø16 SK 40

- For cutters with cross or longitudinal slot

- Including parallel key, driver ring, cutter tightening screw, special wrench

- Thread: M16

Shell End Milling Arbor Ø22 SK 40

SKU: 103900

Shell End Milling Arbor Ø22 SK 40

- For cutters with cross or longitudinal slot

- Including parallel key, driver ring, cutter tightening screw, special wrench

- Thread: M16

Shell End Milling Arbor Ø32 SK 40

SKU: 103910

Shell End Milling Arbor Ø32 SK 40

- For cutters with cross or longitudinal slot

- Including parallel key, driver ring, cutter tightening screw, special wrench

- Thread: M16

Shell End Milling Arbor Ø40 SK 40

SKU: 103915

Shell End Milling Arbor Ø40 SK 40

- For cutters with cross or longitudinal slot

- Including parallel key, driver ring, cutter tightening screw, special wrench

- Thread: M16

ER 40 Collet Chuck / Mount ISO 40

SKU: 106062

ER 40 Collet Chuck / Mount ISO 40

- For clamping tools with cylindrical shank in ER collets according to DIN 6499

ER 40 Collet Set 15 pcs.

SKU: 106075

ER 40 Collet Set 15 pcs.

- 6 pcs: 0.24", 0.31", 0.4", 0.47", 0.6", 0.8"

Clamping Tool Set De Luxe 14/M12

SKU: 105295

Clamping Tool Set De Luxe 14/M12

- 52 parts

- In a convenient, sturdy steel magazine

- 24 stud bolts, 4 each in the lengths 3", 4", 5", 6", 7", 8"

- 4 extension nuts, 6 stepped clamps (3 pair), 6 T-slot nuts, 6 hexagon nuts flanged, step blocks (3 pairs)

HS 125 Hydraulic Machine Vise

SKU: 125024

HS 125 Hydraulic Machine Vise

- Hardened and precision-ground jaws and body

- High precision and wear-resistant material ensure long service-life

- Clamping pressure is up to ten times as high as with conventional machine vises

- Swivel-base mounted vise body, 360° swivel

- Constant clamping pressure, unaffected by vibration and shock

- Hydraulic power booster

Divider ST 130

SKU: 110960

Divider ST 130

- Gear ratio 1:90, disengages for direct division, manual 360° rotation of chuck

- Hand wheel with scale ring

- Nonius division 10''

- 6 masks for direct division of 2, 3, 4, 6, 8, 12, 24 parts

- Hardened and ground teeth with 3-jaw chuck, 6.5" or 7.75"