BO T 130 L CNC

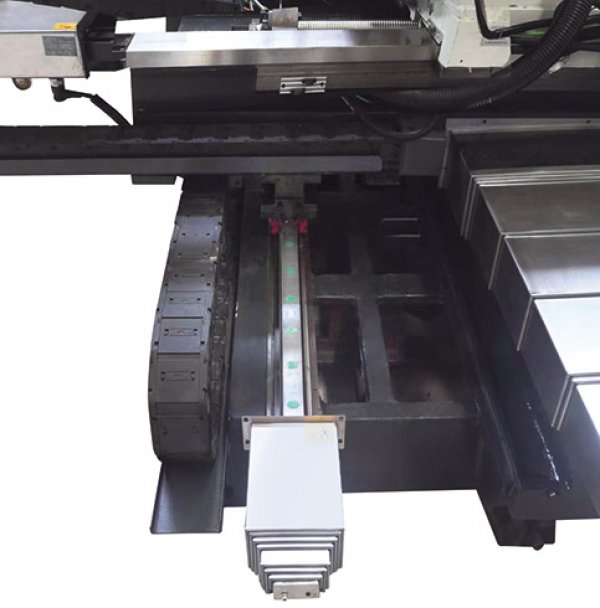

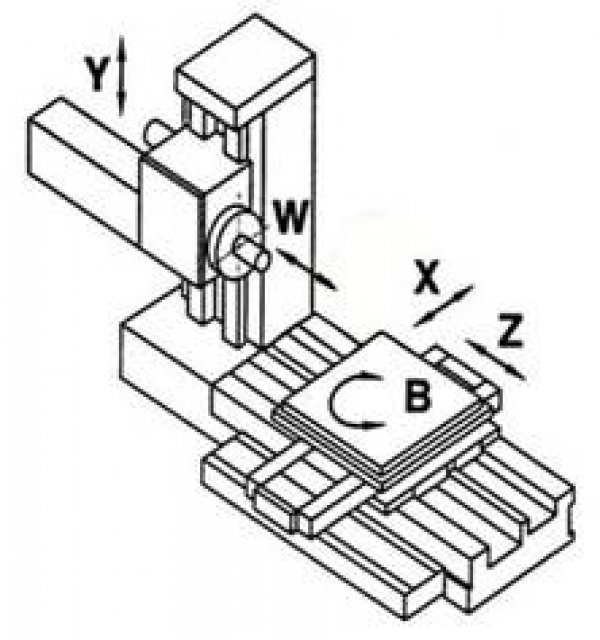

The machines of the BO 130 CNC series are large milling and boring mills that are designed for heavy-duty machining of large and heavy workpieces. The powerful Siemens 828D CNC control and the rotary table for multi-sided machining of workpieces in one clamping offer solutions for a wider range of milling and drilling work.

- Increased table support in X-axis

- Powerful main motor with high torque

- CNC rotary table with 5° steps indexing

- Siemens 828D control for advanced machining