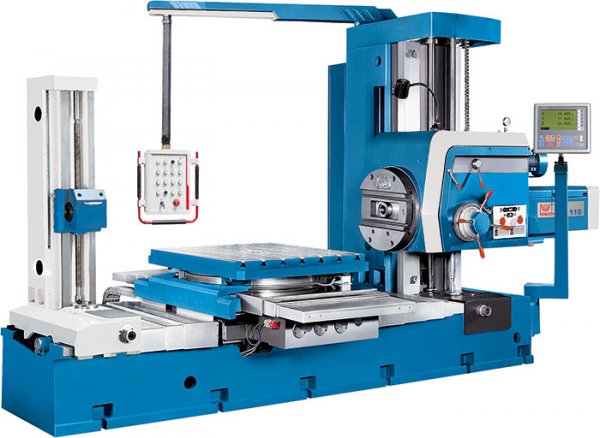

BO 110

The BO series of conventional boring-milling machines is designed for horizontal, multi-sided drilling and milling of workpiece weights of up to 2.5 tons. The stand is fixed, while the table can move and rotate 360°. The drill head moves on the column and the spindle has a long stroke on the W-axis. Conventional boring mills also have a facing slide with a long stroke, which extends the application to include boring. High drive power and automatic feeds on all axes with rapid traverse enable efficient machining and short non-productive times.

- Large work area with W-axis and facing slide

- Thread cutting unit

- Setup table rotates 360°

- Telescoping stainless steel covers on all guides

- Tailstock included