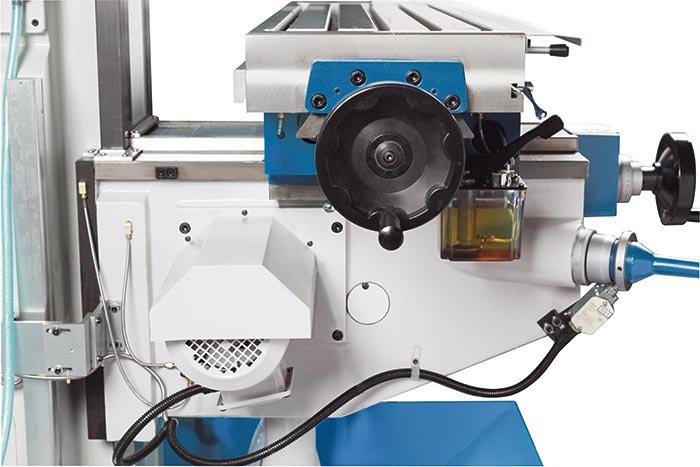

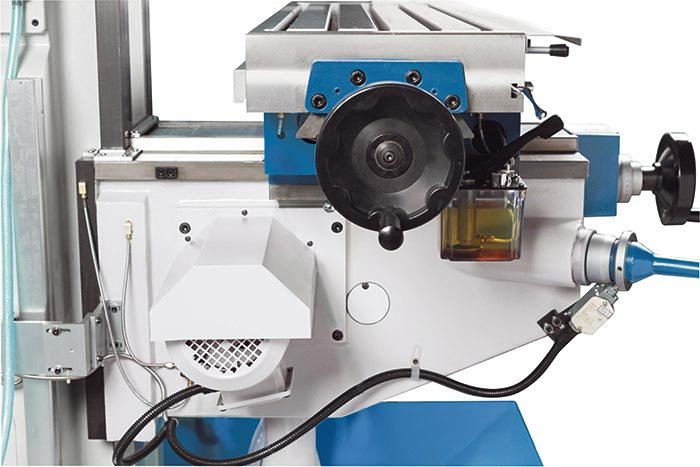

VHF 3

The VHF 3 is a universal milling machine that can keep pace with the growing demands of our customers even after a good 20 years in the KNUTH catalog. Equipped with a horizontal spindle, a swiveling vertical milling head and a large clamping table, this model serves a wide range of applications. The entire VHF series is ideal for repair shops, as well as training and production departments. The complete configuration with automatic feed and digital position display enables precise production and short non-productive times.

- Solid construction for precision machining

- Automatic work feeds on all axes to ensure best surface finish

- Automatic rapid feeds on all axes to minimize downtime

- Swiveling vertical head ± 45° for angle machining

- Automatic quill feed for fast and accurate drilling

- New generation DRO with milling functions