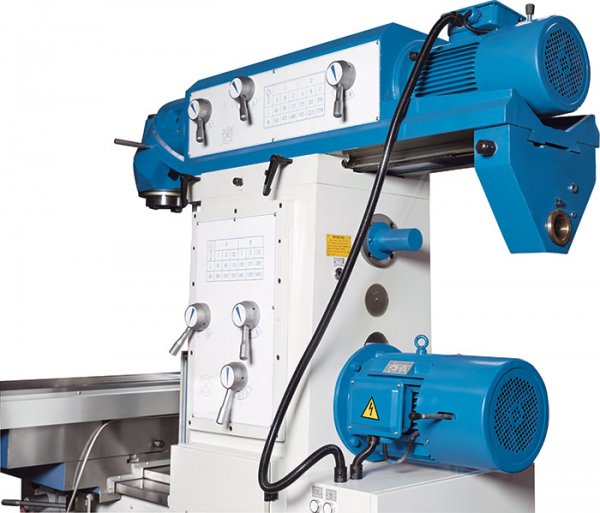

UWF 6

This universal milling machine is the biggest model from UWF series and stands out with its rigid construction, large working area, and extended travels on all axes. Designed as a versatile solution, it can easily handle large workpieces and is packed with features like universal milling head, swiveling table, horizontal axis which greatly increases its range of application.

- Universal cutter head swivels on 2 levels

- Horizontal milling spindle with its own drive

- Swiveling milling table

- Servo-feed on all axes with rapid feed

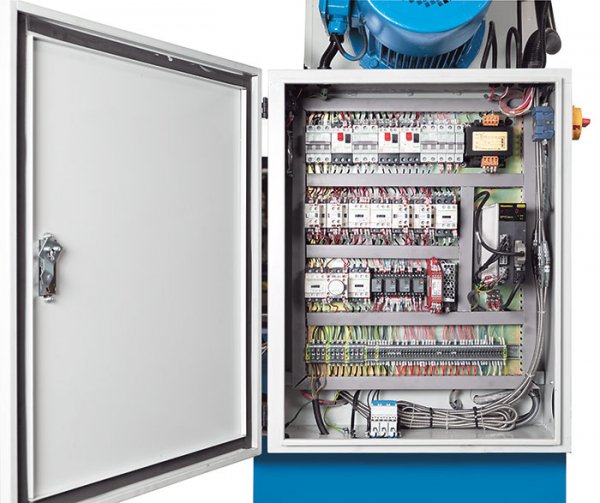

- Extensive standard Equipment