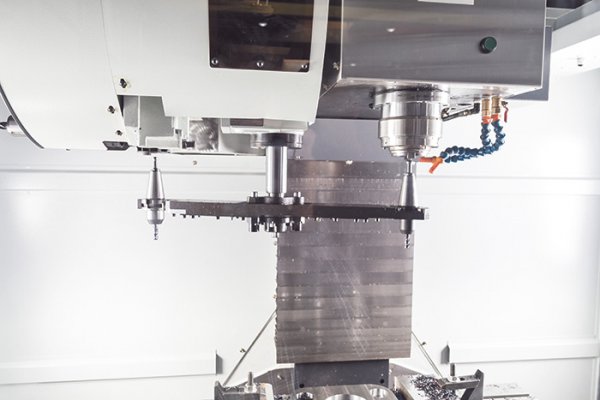

VECTOR 1200 M SI (BT40)

The Vector 1200 series was developed for machining large and heavy workpieces. The heavy machine frame made of Meehanite cast, the robust construction with four guideways on the Y-axis and high-quality components guarantee consistently high cutting performance. You can rely on high precision even in multi-shift operations. A wide range of accessories allows the machines to be expanded into tailor-made complete solutions for specific applications. The series offers automation solutions that enable you to further increase productivity.

- optimized frame design using fem analysis

- spindle on multiple bearings ensure min. vibrations

- 30-bar cts to ensure optimum machining quality

- built for multi-shift production

- high customization and automation possibilities

- 2 years standard warranty