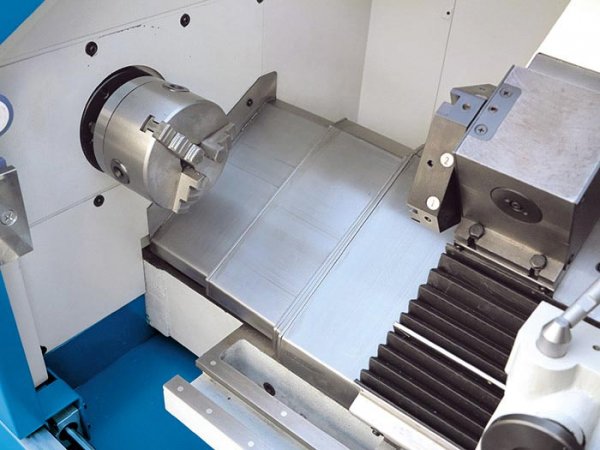

LabTurn 2028

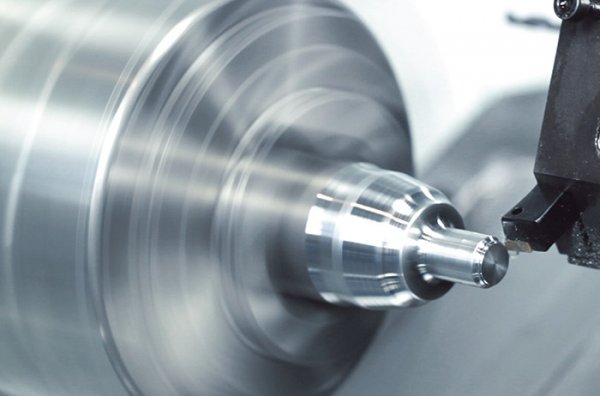

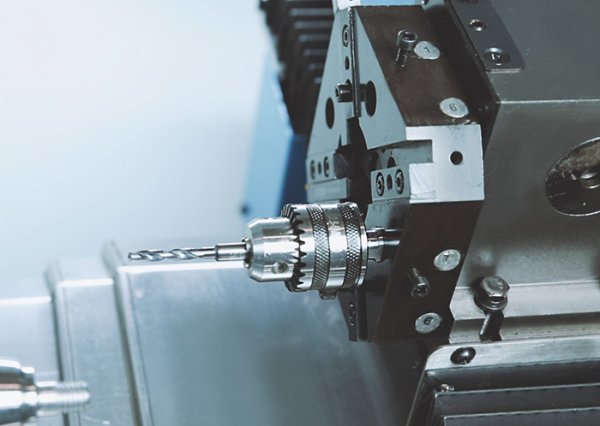

The LabTurn is suitable for CNC training as well as for the production of small workpieces. The compact and mobile CNC lathe represents the full range of functions of a large production machine. The 8-station tool turret has four tools each for internal and external machining and long workpieces can be machined with a tailstock. The main spindle rotates continuously up to 3000 revolutions and the 3-jaw chuck has a diameter of 100 mm (3.9 in). With its simple, intuitive operator guidance, the Siemens 808 controller is the ideal introduction to CNC applications.

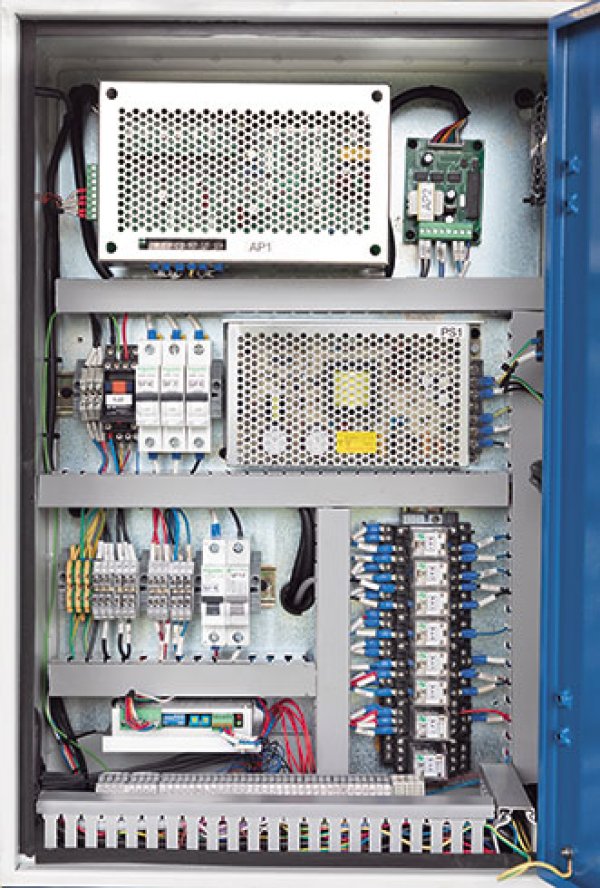

- Siemens 808 Advance

- ideal for entry-level

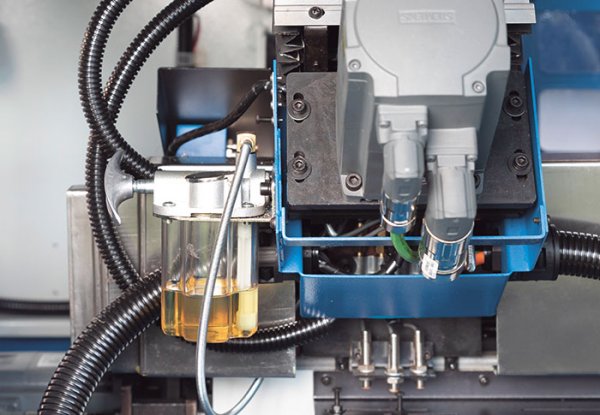

- Tool turret for inside and outside machining

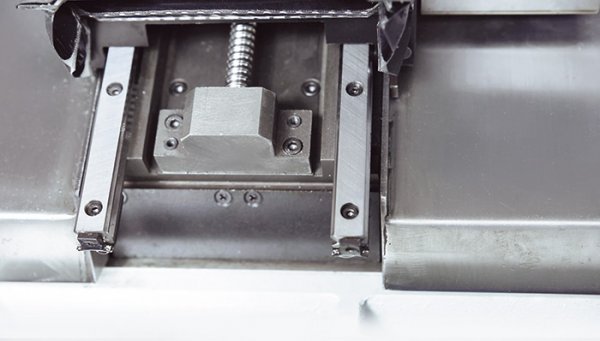

- Linear guides and preloaded ball screws

- Enclosed machine housing

- Mobile base with large storage base