LabCenter 260

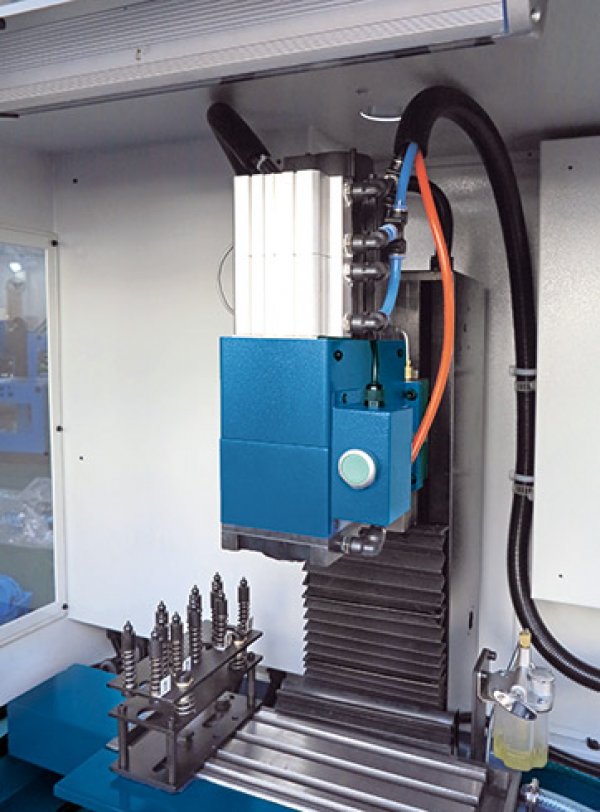

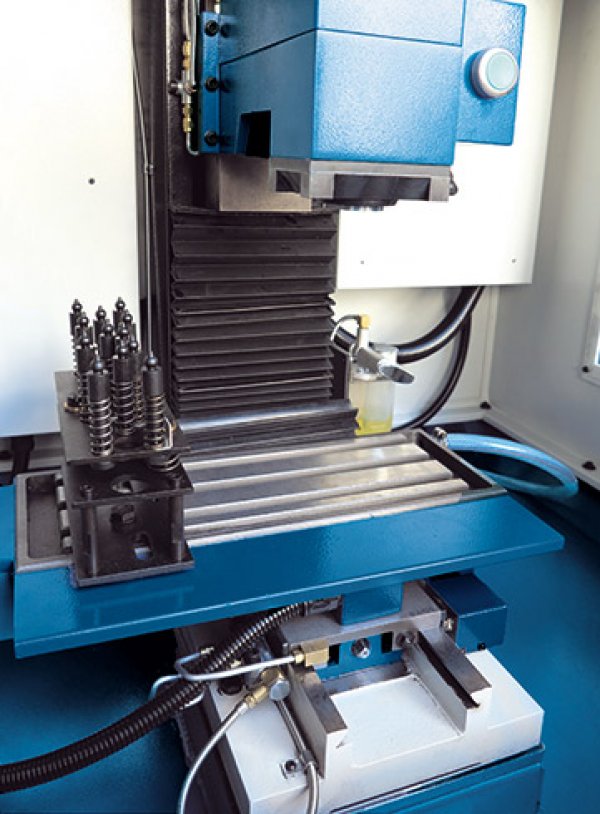

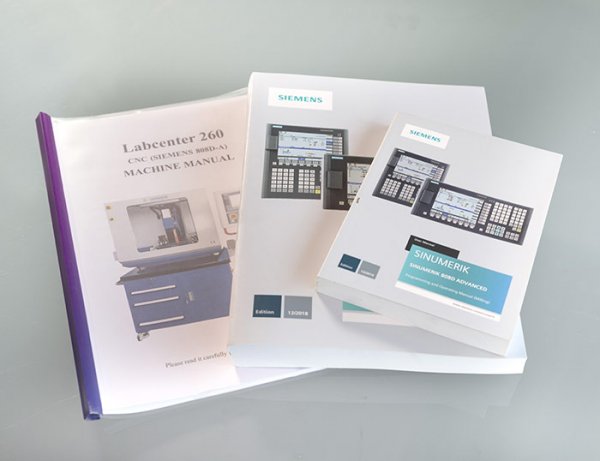

The LabCenter is ideal for CNC training, but also for the production of small workpieces. The compact and mobile CNC machining center represents the full range of functions of a large production machine. The main spindle rotates continuously variable up to 5000 revolutions and the Siemens 808 control offers an ideal introduction to CNC applications with its simple, intuitive operator guidance. With the ISO 20 spindle taper, automatic tool clamping and a 4-way pick-up tool changer, the LabCenter enables practice-oriented training.

- Cast-iron machine frame

- Preloaded ball screws on all axes

- Spindle speeds up to 5000 rpm

- 4-station tool changer

- Mobile base with storage space