Top cover for X.Mill/Vector 650-1000

SKU: 252819

Top cover for X.Mill/Vector 650-1000

Renishaw OMP 40 Workpiece Measuring

SKU: 252820

Renishaw OMP 40 Workpiece Measuring

Connection for 4th axis (wiring only and axis chart)

SKU: 253019

Connection for 4th axis (wiring only and axis chart)

CTS 30 bar system with dual filter system

SKU: 253369

CTS 30 bar system with dual filter system

Siemens Function: P17: Shopmill

SKU: 253377

Siemens Function: P17: Shopmill

Siemens Function: P25: 3D Simulation

SKU: 253378

Siemens Function: P25: 3D Simulation

Siemens Function: P13: Residual Material Detection

SKU: 253379

Siemens Function: P13: Residual Material Detection

Siemens Function: P22: Simultaneous Recording

SKU: 253380

Siemens Function: P22: Simultaneous Recording

Disc Type Oil Skimmer

SKU: 253383

Disc Type Oil Skimmer

Chip Wash System

SKU: 253384

Chip Wash System

Renishaw Tool Setter TS27R

SKU: 253386

Renishaw Tool Setter TS27R

Arm Type BT-40/SK 40 24-Tool-Changer

SKU: 253436

Arm Type BT-40/SK 40 24-Tool-Changer

Measuring Cycles

SKU: 253438

Measuring Cycles

Spindle Oil Cooler

SKU: 253440

Spindle Oil Cooler

Renishaw OTS wireless tool setter (OTS)

SKU: 253598

Renishaw OTS wireless tool setter (OTS)

Ø125mm 4th axis (4th axis, servo motor, driver, air brakes)(Si)

SKU: 253604

Ø125mm 4th axis (4th axis, servo motor, driver, air brakes)(Si)

Ø170mm 4th axis (4th axis, servo motor, driver, air brakes)(Si)

SKU: 253605

Ø170mm 4th axis (4th axis, servo motor, driver, air brakes)(Si)

Ø210mm 4th axis (4th axis, servo motor, driver, air brakes)(Si)

SKU: 253606

Ø210mm 4th axis (4th axis, servo motor, driver, air brakes)(Si)

Ø250mm 4th axis (4th axis, servo motor, driver, air brakes)(Si)

SKU: 253607

Ø250mm 4th axis (4th axis, servo motor, driver, air brakes)(Si)

Spindle speed upgrade 10.000 to 12.000 rpm (belt type)

SKU: 253609

Spindle speed upgrade 10.000 to 12.000 rpm (belt type)

Spindle speed upgrade to 12.000 rpm direct drive no CTS

SKU: 253610

Spindle speed upgrade to 12.000 rpm direct drive no CTS

Arm type ATC upgrade from 24 to 30 tools (BT40) for X.Mill T

SKU: 253611

Arm type ATC upgrade from 24 to 30 tools (BT40) for X.Mill T

Upgrade from screw type to chain type chip conveyor

SKU: 253612

Upgrade from screw type to chain type chip conveyor

preparation for Renishaw OMP40

SKU: 253613

preparation for Renishaw OMP40

manual tailstock ST-125T for rotary table for X.mill

SKU: 253617

manual tailstock ST-125T for rotary table for X.mill

manual tailstock ST-170T for rotary table for X.mill

SKU: 253618

manual tailstock ST-170T for rotary table for X.mill

manual tailstock ST-255T for rotary table for X.mill

SKU: 253620

manual tailstock ST-255T for rotary table for X.mill

manual 5'' chuck for rotary table for X.mill

SKU: 253621

manual 5'' chuck for rotary table for X.mill

manual 6'' chuck for rotary table for X.mill

SKU: 253622

manual 6'' chuck for rotary table for X.mill

manual 9'' chuck for rotary table for X.mill

SKU: 253624

manual 9'' chuck for rotary table for X.mill

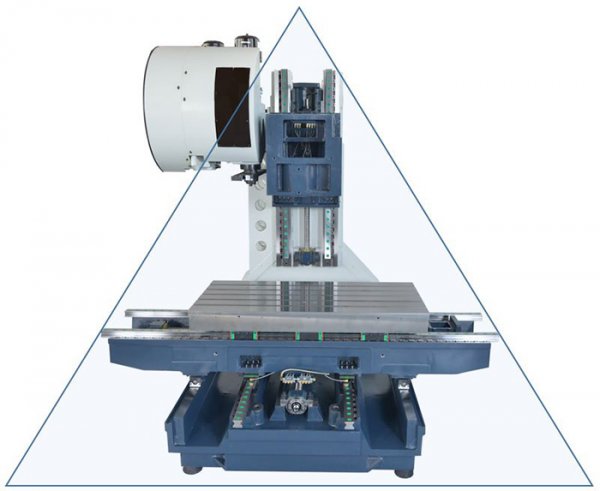

Z axis travel upgrade from 550 to 800 mm for X.mill

SKU: 253625

Z axis travel upgrade from 550 to 800 mm for X.mill

Z axis travel upgrade from 550 to 800 mm for X.mill

SKU: 253626

Z axis travel upgrade from 550 to 800 mm for X.mill

CTS 20 bar system with dual filter system

SKU: 253627

CTS 20 bar system with dual filter system

Upgrade from 10.4” to 15” touch screen (for PPU260 or higher)

SKU: 253674

Upgrade from 10.4” to 15” touch screen (for PPU260 or higher)

Renishaw OMP 60 workpiece measuring system (BT40)

SKU: 253681

Renishaw OMP 60 workpiece measuring system (BT40)

Air through spindle for Vector

SKU: 253782

Air through spindle for Vector

Upgrade from 828D PPU260 to 840DSL IPC447E 10.4" for Vector

SKU: 253835

Upgrade from 828D PPU260 to 840DSL IPC447E 10.4" for Vector

Upgrade Spindle Taper from SK40 to BBT 40

SKU: 253951

Upgrade Spindle Taper from SK40 to BBT 40

SinuTrain for SINUMERIK Operate Version 4.8

SKU: 423314

SinuTrain for SINUMERIK Operate Version 4.8