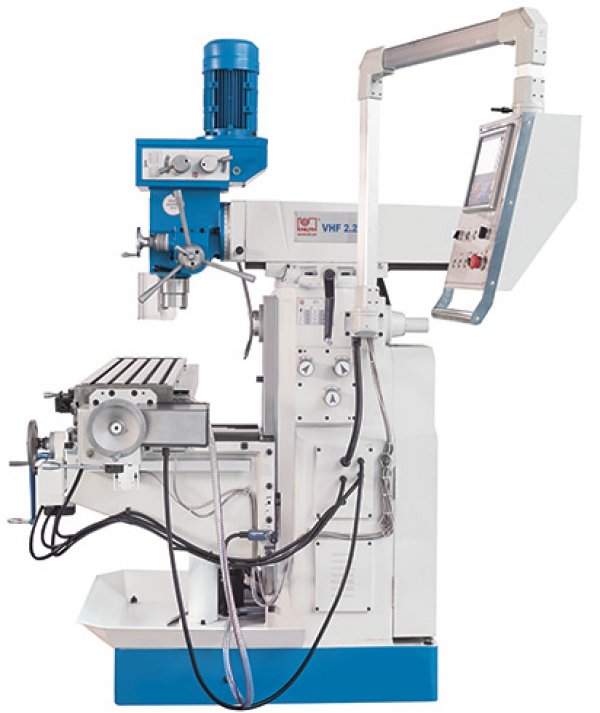

VHF 2.2

VHF series machines feature large travels, a vertical and horizontal spindle with separate drives for powerful machining The vertical head swivels out (±45°) and the quill is movable. All models of this series are ideally suited for applications in repair shops or training shops.

- Tilting vertical milling head

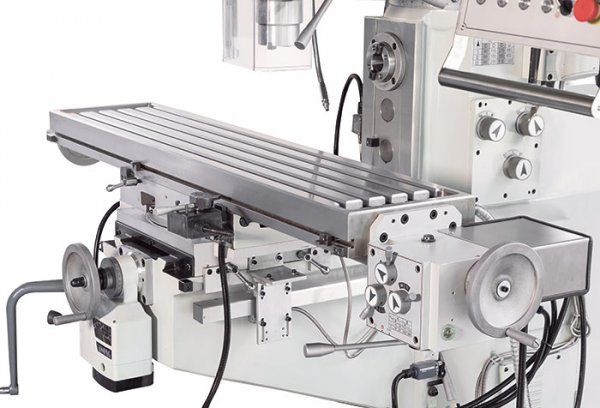

- Automatic feed in X and Y axes

- Horizontal spindle with counter holder

- Extensive package of standard accessories