VECTOR 1300 M HDH

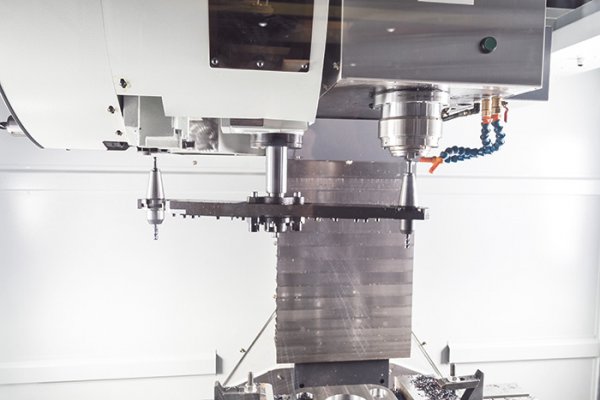

The Vector 1300/1400 series is the perfect solution for machining very large and heavy workpieces. The innovative design of the machine base made of high-quality Meehanite casting with a low center of gravity, and the use of only the highest quality components guarantee the consistently high precision even in multi-shift production. Thanks to a wide range of accessories, the machining centers become a tailor-made complete solution for specific applications. KNUTH also offer automation solutions for this series, with which you can increase your productivity even more.

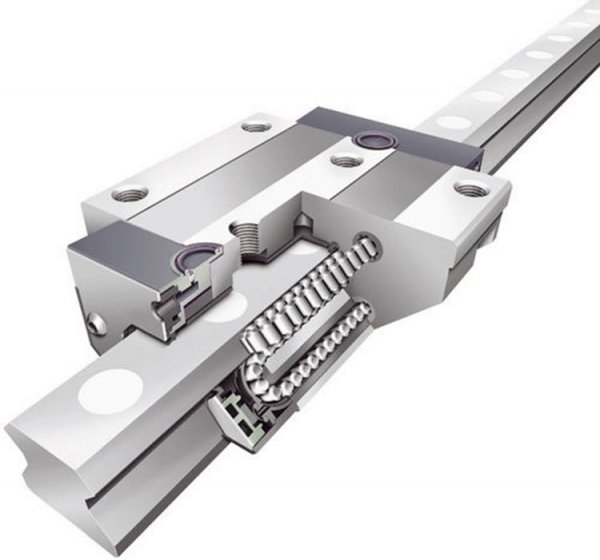

- Optimized frame design using FEM analysis

- Spindle on multiple bearings ensure min. vibrations

- 30-bar through-spindle coolant to ensure optimum machining quality

- Built for multi-shift production

- High customization and automation possibilities

- 2 years standard warranty