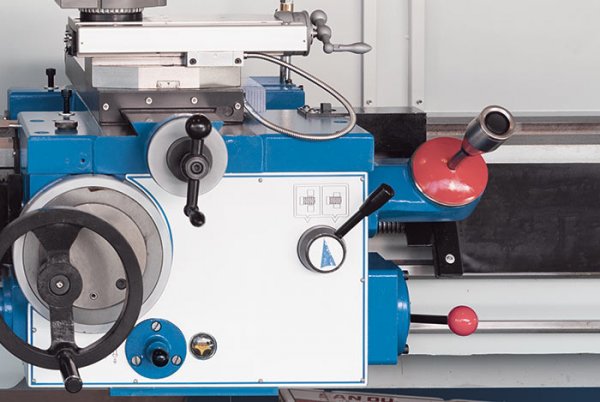

Turnado 280/1500 PRO

The machines of the Turnado PRO series are the modern version of the classic lathe. The PRO models are the latest generation of our universal lathes, which have been tried and tested for 20 years. With constant cutting speed, rapid traverses and an extended speed range that can be controlled by an inverter, these models are characterized by high-performance machining, excellent surface quality and time efficiency. They are easy to recognize by the new ergonomic cladding design, which integrates all functions into an overall concept.

- Classic design with sturdy construction

- built to last

- Motorized rapid feeds for fast positioning

- High motor power with inverter and spindle speed display

- 3-axis position indicator with various turning functions

- Constant cutting speed for superior surface quality

- Extensive standard equipment package