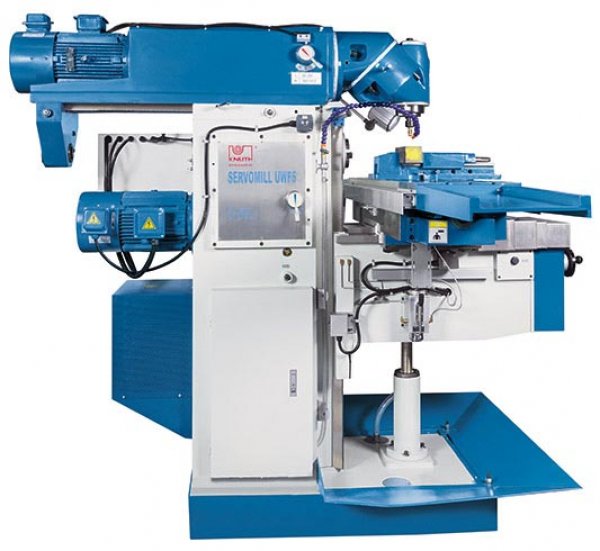

Servomill® UWF 5

The servo-conventional universal milling machine has the latest CNC technology, but can be operated conventionally. In addition to the universal milling head, which can be swiveled in two planes, the machine is also equipped with a horizontal spindle and a more powerful main spindle drive. The servomotor feed with electronic handwheels and the additional milling functions make the advantages of CNC technology accessible without programming. With its extensive equipment, this model is ideal for repair workshops as well as training and fabrication departments.

- Servo-conventional feed technology

- Preloaded ball screws on all axes

- Electronic hand-wheels

- Universal cutter head with 2 swivel axes

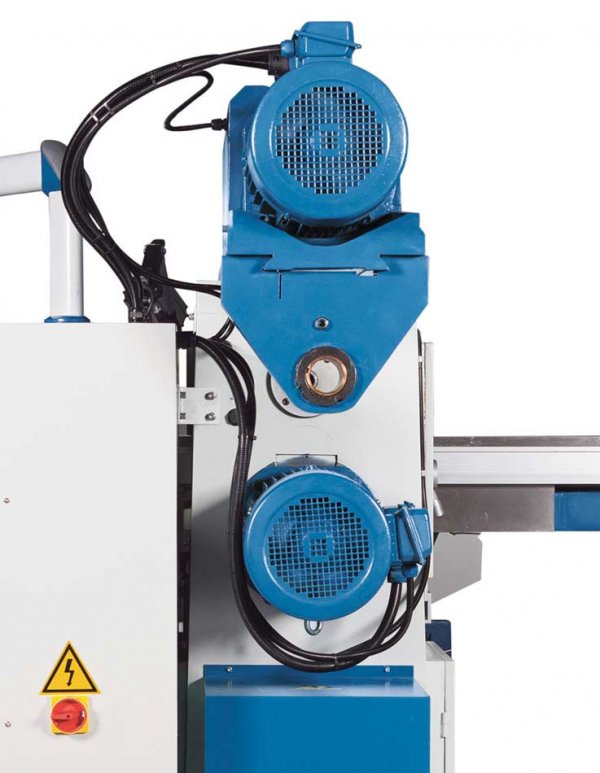

- Horizontal spindle with its own drive