SBF 40 TV 1000

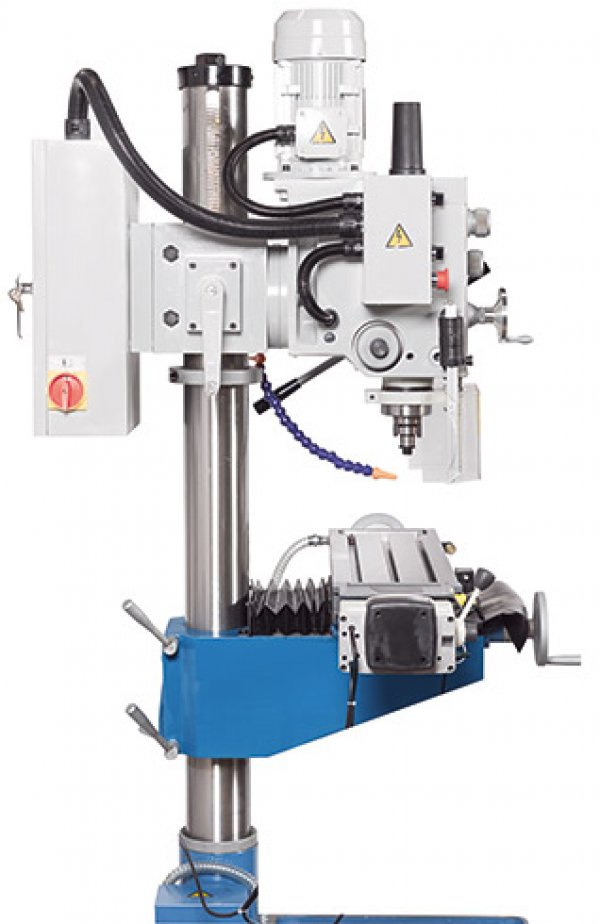

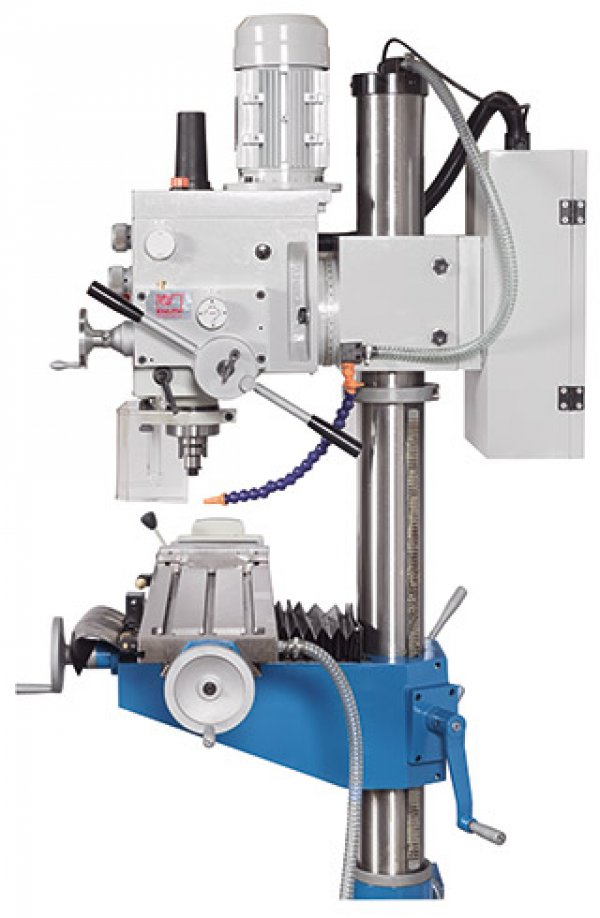

The SBF is a drilling and milling machine in the best way. It is ideal as a drill with a powerful drive and a wide speed range. You can also use this machine to mill steel and non-ferrous metals. This makes the SBF 40 a drill with additional benefits at an unbeatable price.

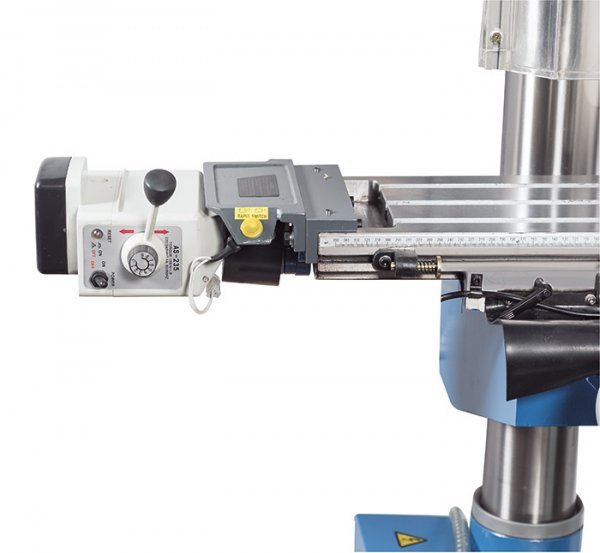

- Extended table length with auto feed on X-axis

- Automatic drilling feed with depth display

- Gearbox milling head for powerful machining

- Swiveling head for wide range of applications