KHT H 4010 CNC

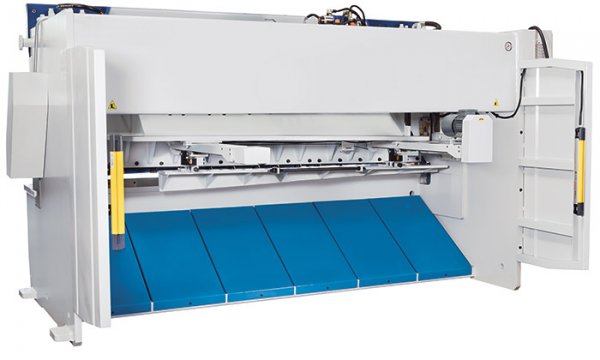

The guillotine shears of the KHT H CNC series are produced in a state-of-the-art manufacturing facility. The construction with a guided cutter bar with adjustable cutting angle guarantees minimal twisting in the workpiece and thus reduces rework. The control is operated on a touchscreen. Cutting gap, cutting angle and cutting length are automatically optimally positioned. The high-quality backgauge is robust and precise, and the standard blades are suitable for stainless steel. Additional accessories expand the range of applications of the guillotine shears.

- Cybelec Touch 8 control

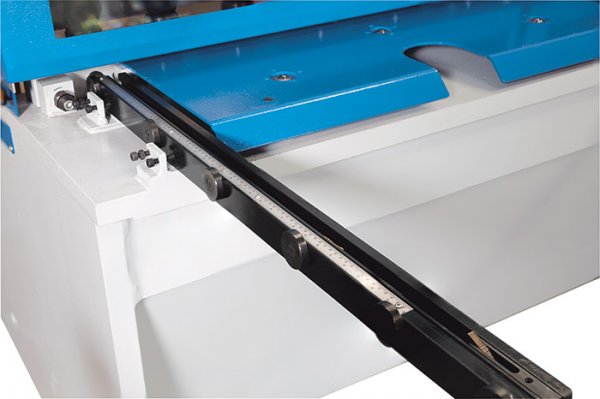

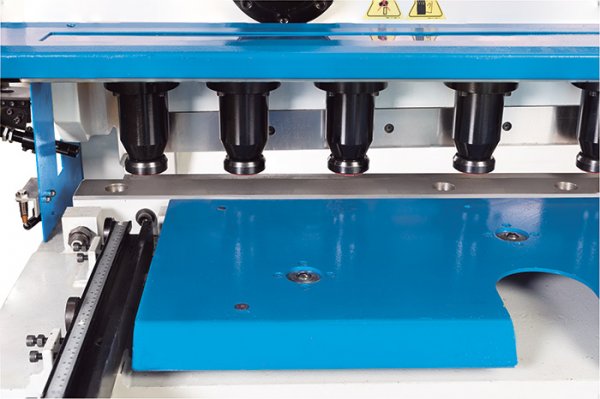

- Controlled kerf adjustment

- Controlled cutting length adjustment

- Controlled cutting angle adjustment

- Blade suitable for stainless steel