KHP 40 NC

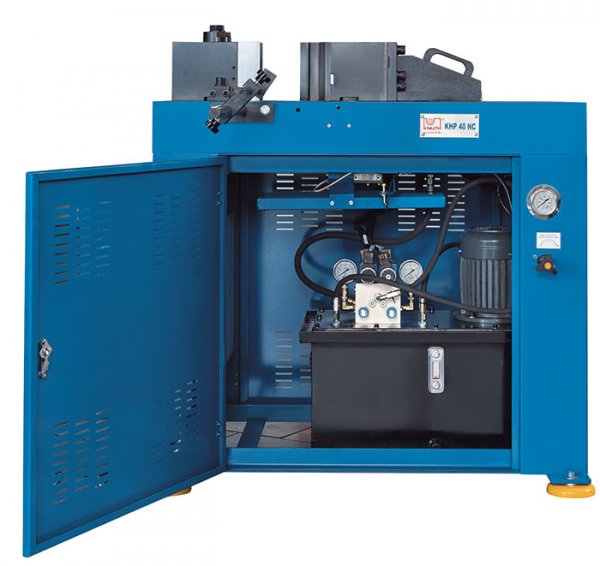

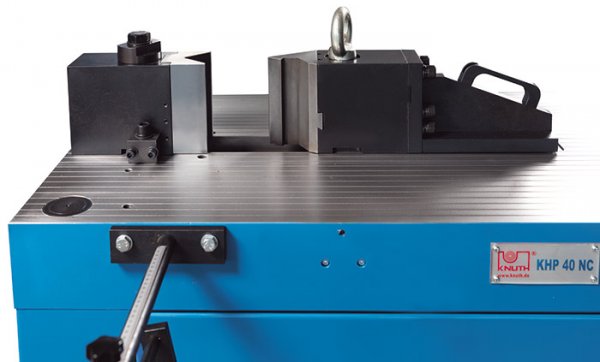

The KHP 40 NC bending and straightening press series is equipped with a punch and a die with a height of 160 mm (6.3 in). Thin sheet metal strips and also thicker flat steel can be processed particularly easily. The pressing force is adjustable and a pressure gauge shows the current bending pressure. The depth stop is set using the touchscreen display. Operation is via a safety foot switch. This machine is also interesting for users who do not want to retool their press brake or who do not want to load it with short pieces.

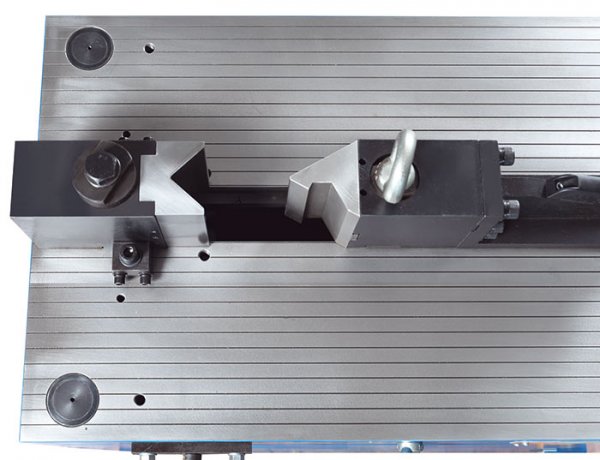

- Female die with 60 mm (2.36 in.) width

- Control panel with touchscreen display

- Pressure gauge for bending force

- Operation via foot switch