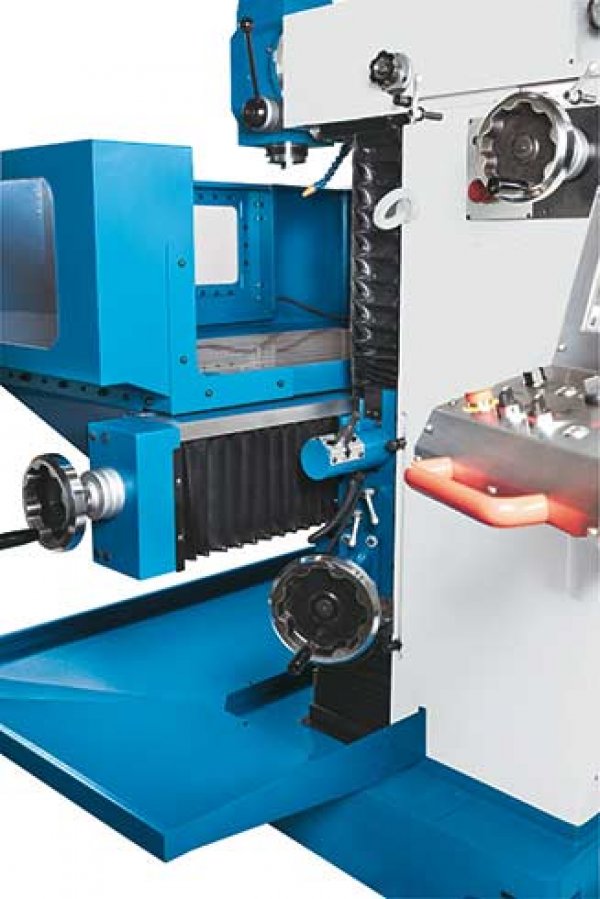

FPK 6.2

Versatile tool milling machine for mechanical production of tools and dies. The compact design offers high flexibility, is easy to operate, and has a widely proven record. Preloaded ball screws on all axes ensure high precision, which makes this machine ideal for tool and die construction, repair shops, training and production facilities.

- Vertical and horizontal spindle

- Infinitely variable feed

- Swiveling vertical cutter head

- Preloaded ball screws on all axes

- Extensive standard equipment package