X.mill 400 (SK40)

This model is very popular with customers who are looking for a quick, inexpensive solution for smaller workshops or who want to convert from conventional to CNC machining.

- Compact design with small footprint

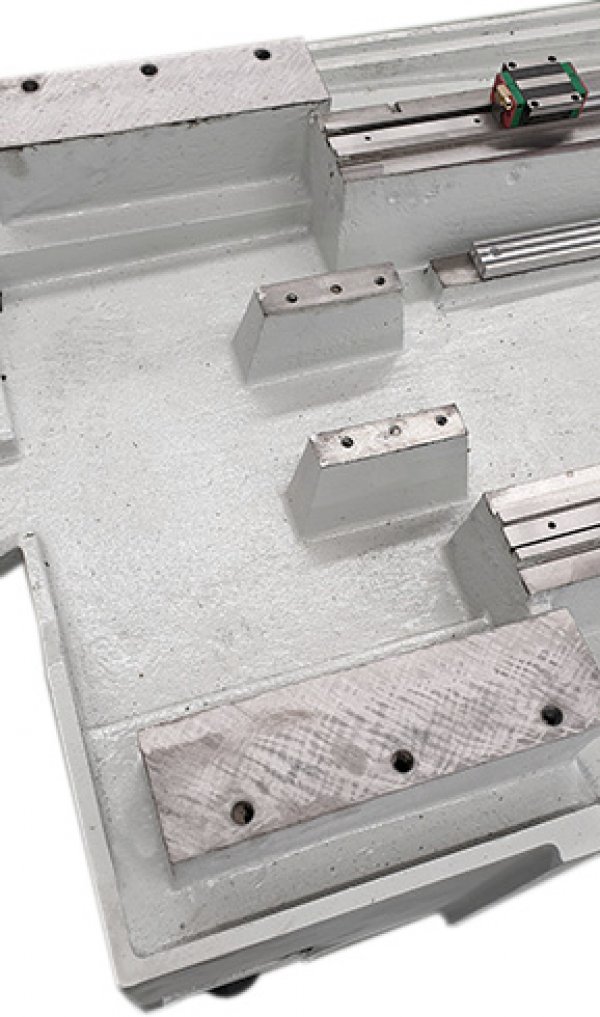

- Built to last robust machine body

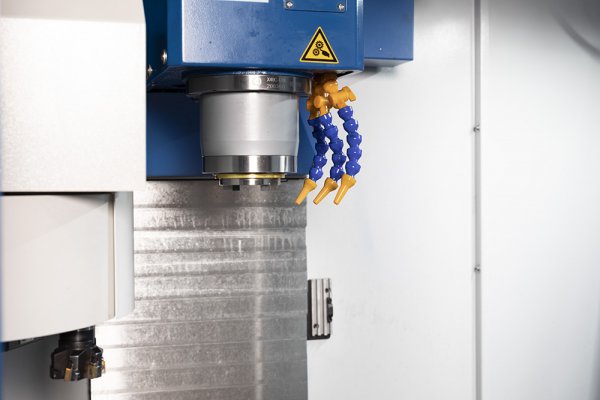

- Oil cooled powerful spindle

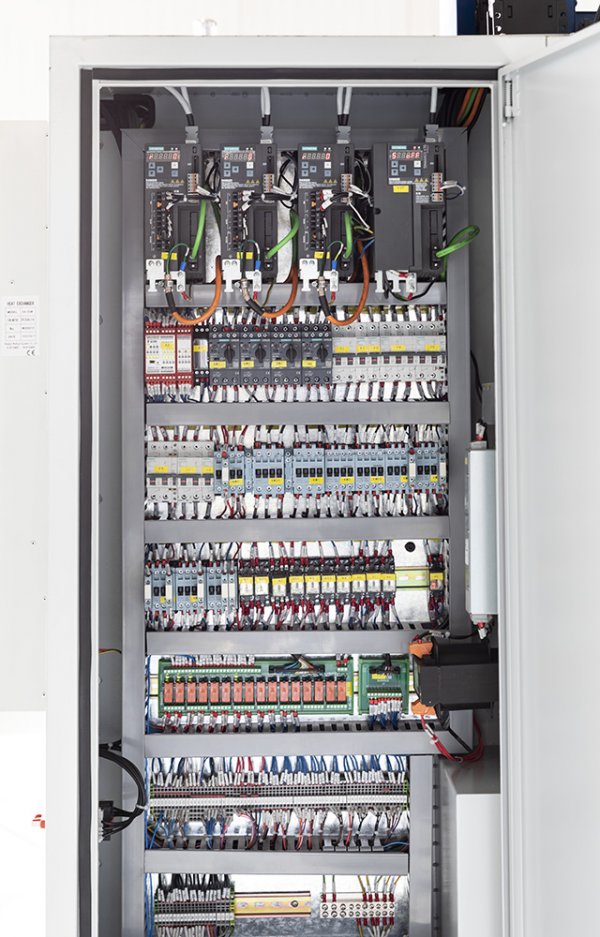

- Air-conditioned electrical cabinet