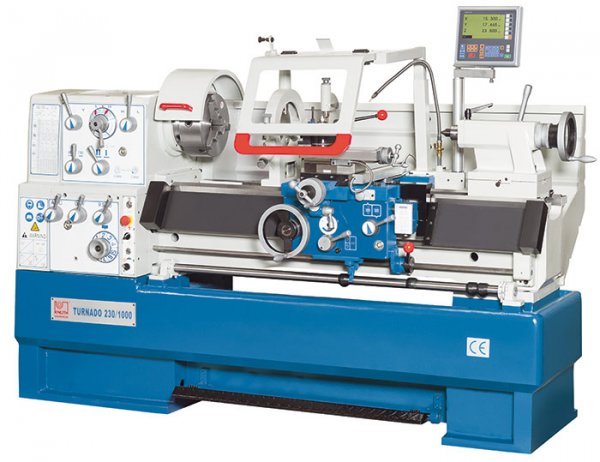

Turnado 230/1000

The machines of the Turnado series are the modern version of the classic lathe. They are characterized by robust construction, a powerful motor and high level of versatility. With the extensive range of standard accessories and options, these machines can be adapted to many production requirements. A modern position indicator is also part of the standard equipment, as is a high-quality quick-change toolholder system. The models in this series have proven themselves many times and have been one of our best-selling conventional lathes for more than 20 years.

- Classic design with sturdy construction

- built to last

- 3-axis position indicator with various turning functions

- Extensive standard equipment package