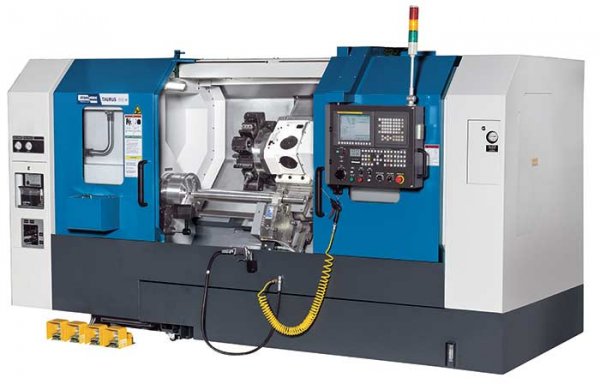

Taurus 300LM

The Taurus series is part of our premium machine program STAHLWERK and specializes in the manufacture of large and complex parts. Thanks to the combination of excellent, South Korean manufacturing quality and high-quality components from well-known suppliers, the heavy CNC centers with solid flat guides meet the highest quality standards. All models have a one-piece, robust 45 degree machine bed with an extra wide saddle, a powerful spindle and a programmable tailstock. The BMT tool turret is optimized for quick tool changes.

- 45° extra wide monoblock machine bed

- Block guideways for maximum rigidity

- Programable tailstock and quill

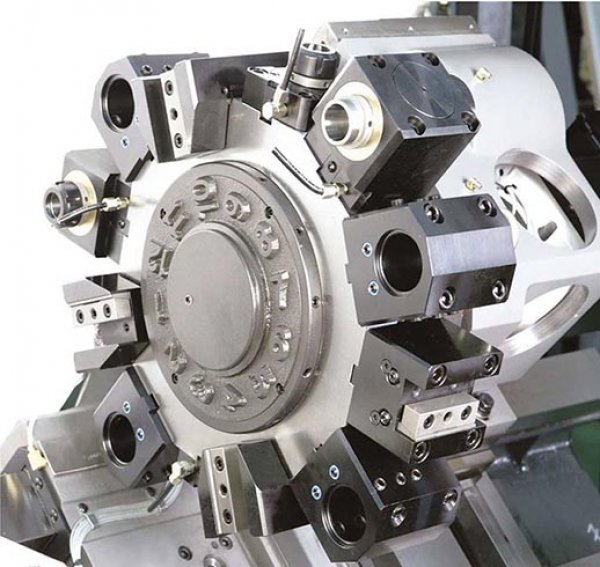

- Bi-directional BMT power turret for complex applications

- Heat distortion prevention system

- High productivity for multi-shift operation

- Extensive options list for customized and automated solutions