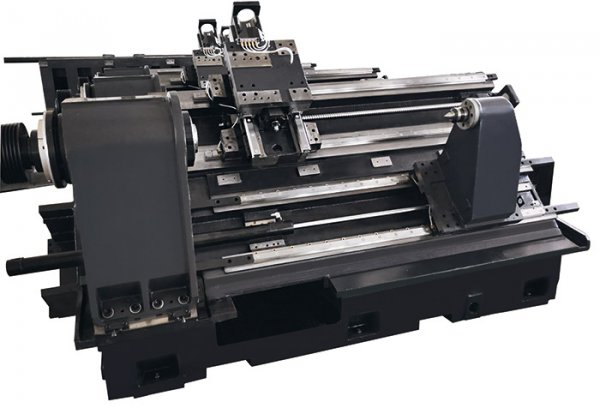

Starchip 560 L

This StarChip Series machine has all the features of a classic CNC production lathe. The modern Siemens control meets all requirements for advanced control technology. The machine features an inclined bed with 12-station tool turret and a powerful 15 kW main spindle motor, including a hydraulic 3-jaw chuck with through-hole. A hinged belt conveyor and a highly efficient coolant system complete the equipment package.