RBM 25/16 NC Teach In

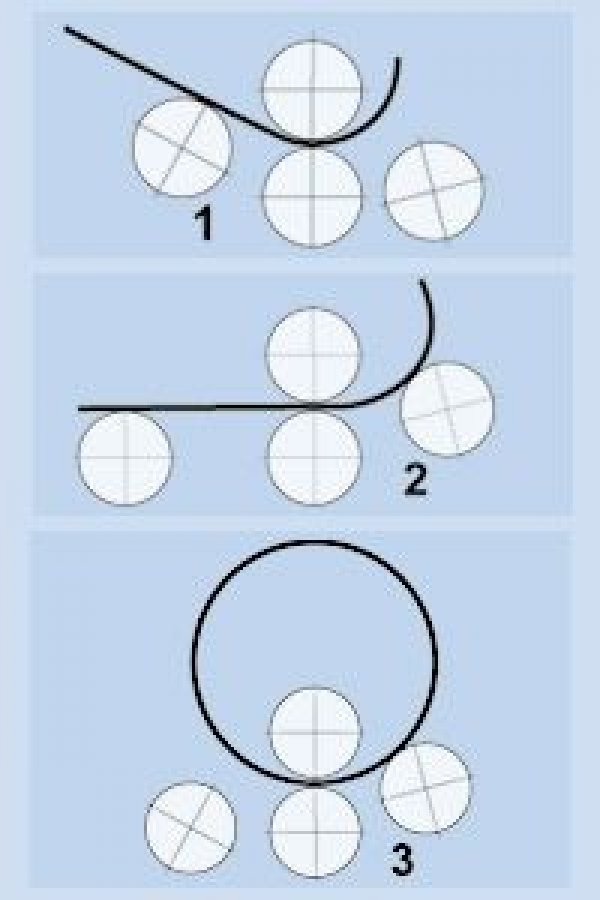

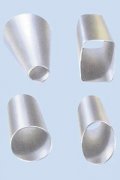

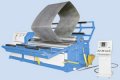

RBM is a series of 4-roll bending machines that are particularly suited for large sheet metal thicknesses. The advantage of this design is that the bending process is done in one operation. The NC control also enables the work steps carried out to be saved and automatically repeated. Special features such as conical bending can be controlled via the control panel. This means that the models in this series can be used for a wide range of applications in shipbuilding, steel and container construction.

- Bending solution for thick materials

- NC-Teach-In programming

- 4 rollers with symmetrical structure

- Hydraulic roller drive

- Hardened rollers and conical bender