Portamill Duo 3012

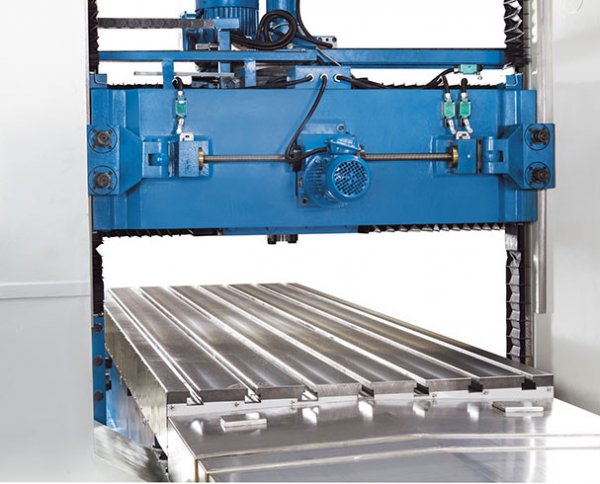

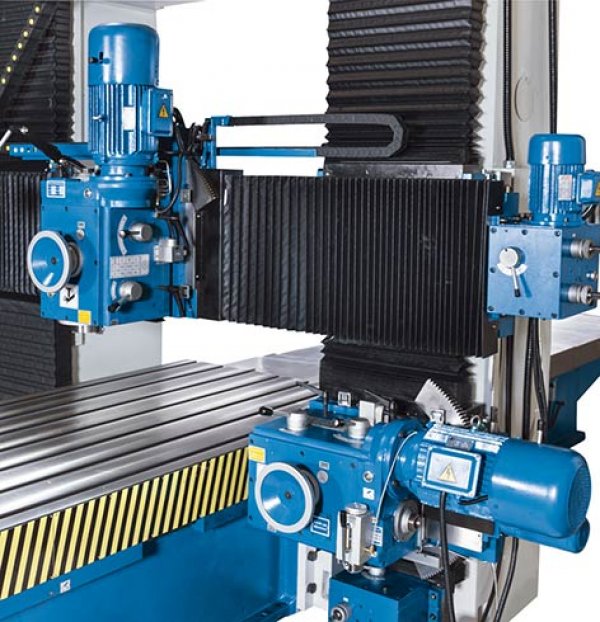

The Portalmill Duo series is designed with a fixed portal and a height-adjustable traverse. A horizontal milling unit, which can be positioned independently of the crossbeam, expands the machine's application possibilities. Based on the hydrostatic principle, the table moves easily and almost wear-free on wide guides. The large clamping table offers plenty of space for workpieces and clamping devices up to a weight of 6000 kg. Together with the extensive equipment, this model is also ideally suited for plant and industrial equipment manufacturing.

- Rigid structure with firmly integrated gantry

- Vertical and horizontal spindle head

- Setup table is supported across the entire travel distance

- Hydrostatic table guide

- For workpiece weights up to 6,000 kg (13,228 lbs)