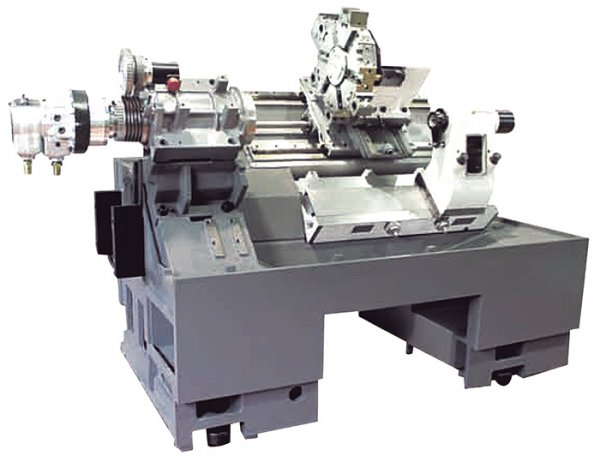

Orion 6TLM

The Orion series is part of STAHLWERK's premium machine program, which combines excellent South Korean manufacturing quality with high-quality components from well-known suppliers. The new generation of high-speed CNC turning centers impresses with a robust, one-piece 45 degree machine bed, high-quality linear guides and bi-directional servo turrets. The machines of the Orion series are built for multi-shift operation and guarantee a quick return on investment thanks to their high efficiency.

- Compact design with very small footprint

- Extra-wide 45° inclined bed in a monoblock design

- Linear guideways for high-speed machining --VDI servo turret with 0.2 sec indexing time

- High productivity with multi-shift work capabilities

- Extensive option list for customized and automated solutions