NeoSpark B 500

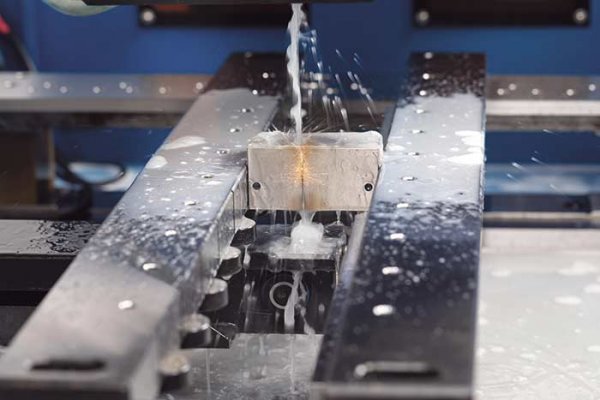

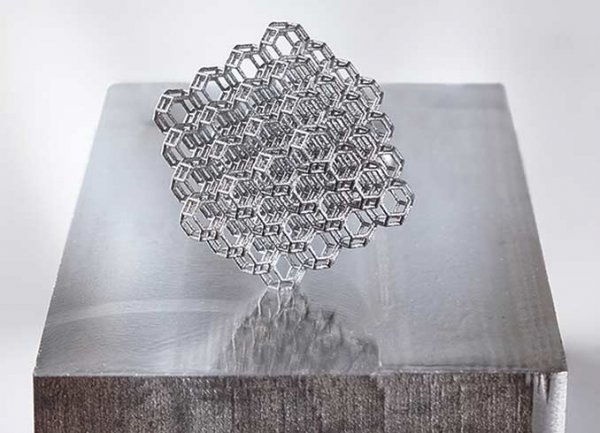

The machines of the NeoSpark CNC series are among the most precise wire EDM machines with reciprocal wire guidance on the market. They offer excellent performance when machining electrically conductive materials in mold and tool making. The NeoSpark series is a popular choice for companies that specialize in additive manufacturing and want to separate the finished part from its base plate with high precision. High speed wire cutting guarantees deformation-free and burr-free cutting of even the most delicate 3-D printed metal structures with the best surface quality.

- Reciprocal wire design with very low operation costs

- Servo drives and multi-pass technology for precise machining

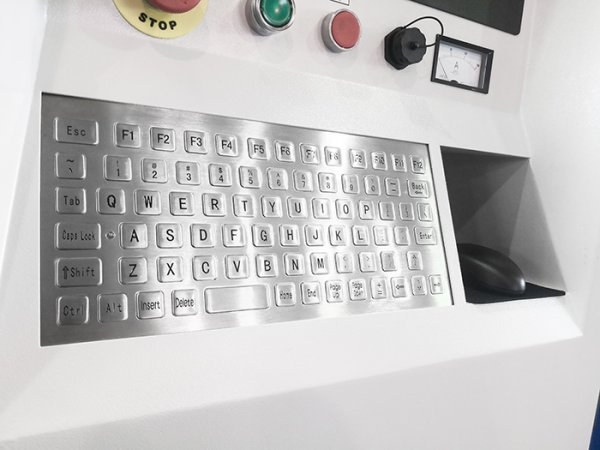

- Easy programming on Windows based IPC controller

- Extended cnc functions for full process control

- Max. safety in operation with real time auto-diagnostics

- Programming during machining for min. downtime