HFS 160 NC

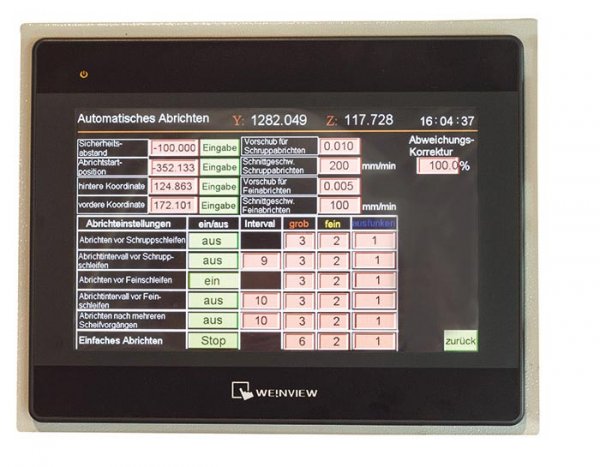

The HFS NC series is a solution for automatic and semi-automatic surface and flute grinding. This machine offers advantages in terms of precision and efficiency thanks to grinding cycles that can be easily programmed via the touchscreen and the automatic grinding wheel dressing mode. This can be inserted into the machining cycles and compensates dimensions and speed fully automatically. The option of switching between semi-automatic and automatic operation also extends the range of applications from repair workshops and training to series production.

- Automatic grinding wheel dressing cycle

- Magnetic table and built-in demagnetization feature

- Vertical axis with ball screw and servo motor for high precision

- Easy auto-mode programming

- Extensive standard equipment package