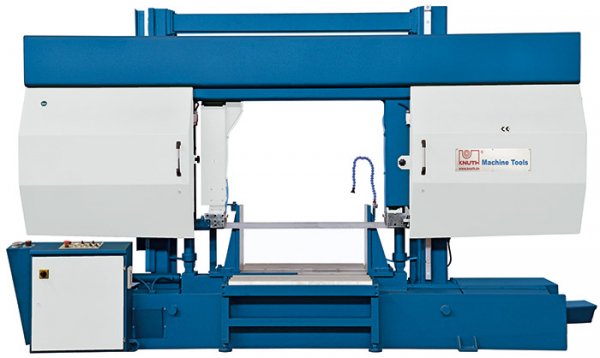

HB 810 L

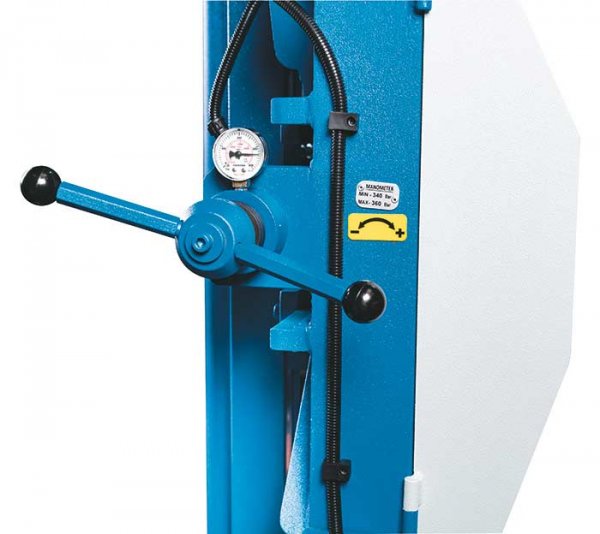

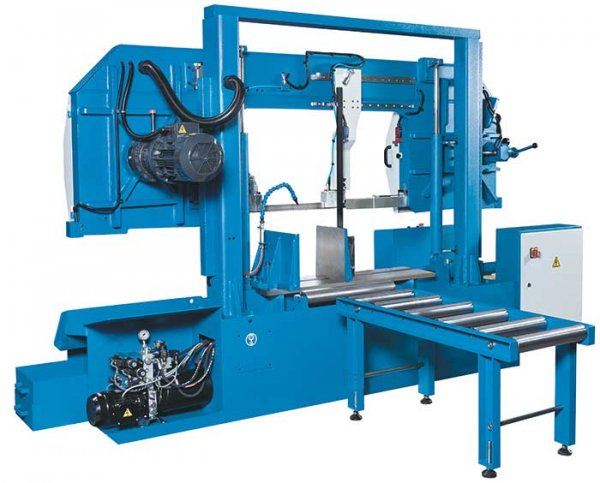

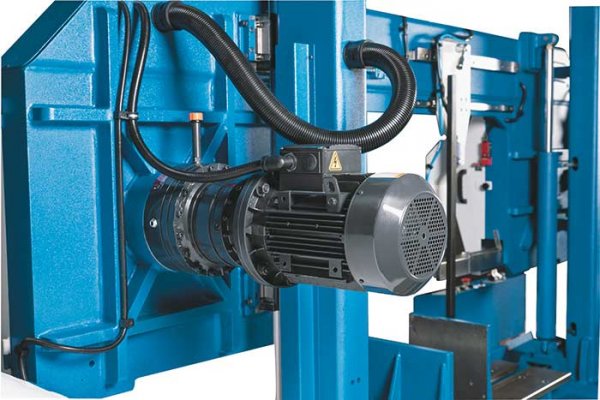

The semi-automatic horizontal band saws of the HB-L series are the first choice for applications in the category of heavy cutting. They cut heavy workpieces made of steel, cast iron and other materials with high precision. The machines are characterized by a rigid and extremely stable dual column construction. Reduced vibrations enable shorter cutting times and higher accuracy. Functions such as the finely adjustable saw blade feed, the continuously adjustable saw blade speed and the swiveling workpiece clamping contribute to the excellent cutting performance of the HB-L series.

- Dual column design with linear guide

- Semi-automatic operation

- Automatic stroke height adjustment with optical sensor

- 45° swiveling vise for miter cutting

- Short setup time for machine and workpiece