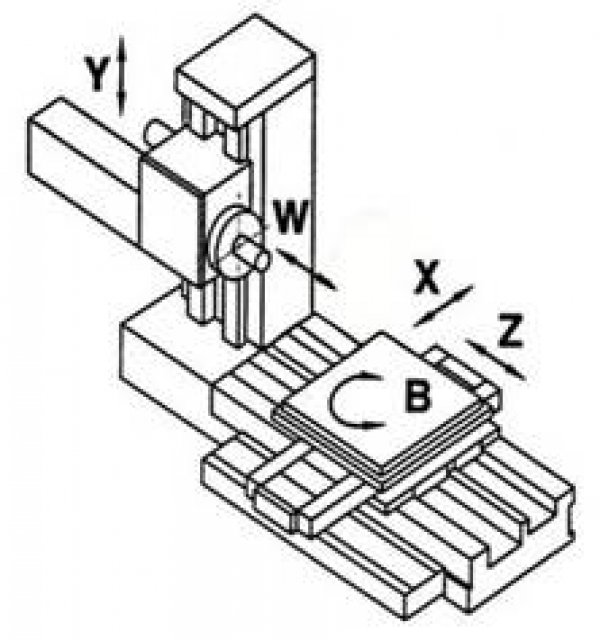

BO T 110 L CNC

With the large milling and boring mills of the BO 110 CNC series, heavy-duty machining of large and heavy workpieces is possible. The powerful Siemens 828D CNC control and the 4-position indexing turntable for multi-sided machining of workpieces in just one clamping, create solutions for a broader range of your milling and drilling work.

- Manual rotary table with 4 positions indexing

- Powerful main motor with high torque

- Siemens 828D control for advanced machining