AHK H 30175 CNC

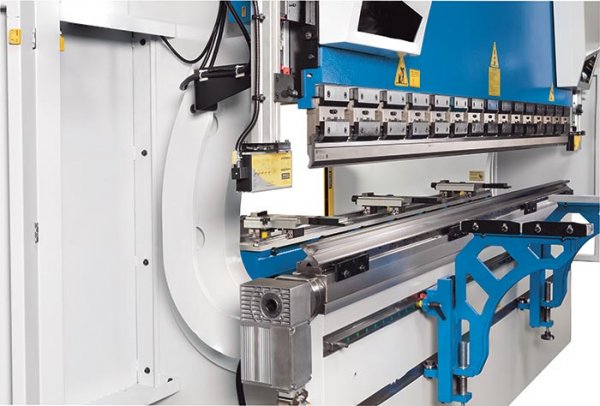

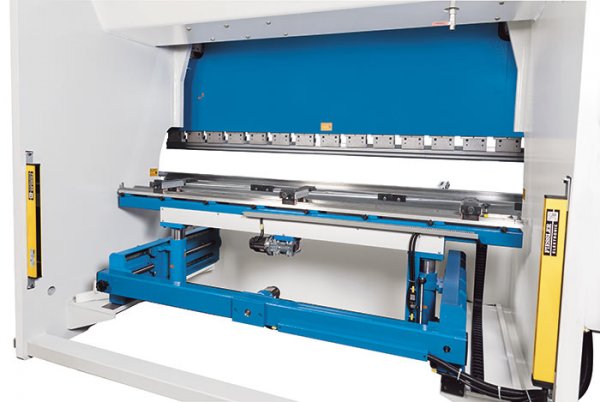

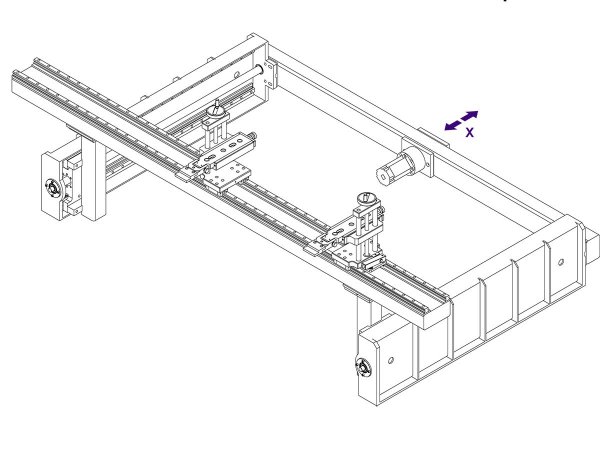

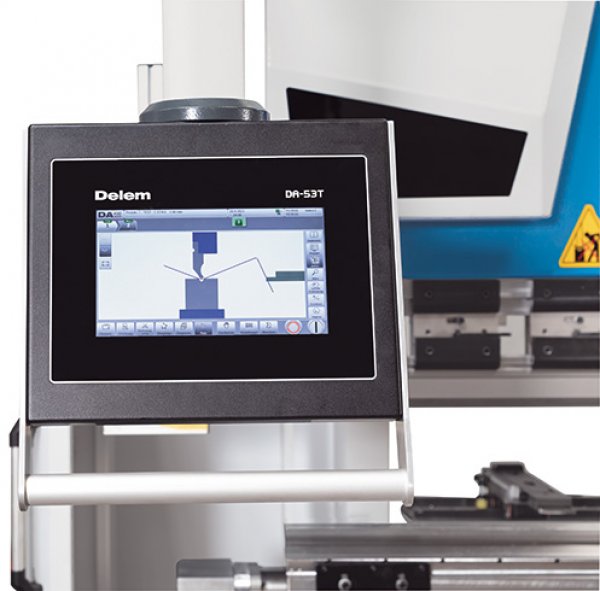

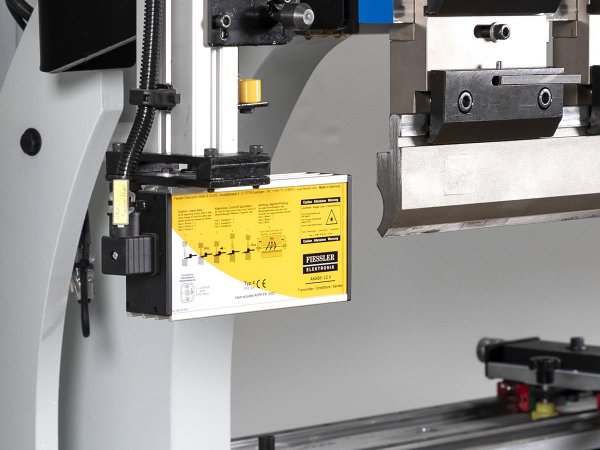

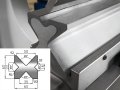

The press brakes of the AHK-H series are among our bestsellers. This series meets all expectations in terms of stability, precision and durability. Developed with the latest construction technology and built on the latest production lines, the AHK-H series is equipped with a graphic touchscreen control from DELEM. This offers powerful CNC programming and full control over the entire bending process. In combination with the various options for the back gauge, these press brakes can be adapted to a wide range of requirements.

- Built with advanced technologies for high performance

- Excellent bending precision

- Delem controller for advanced bending solutions

- 4-axes CNC standard for large range of operations

- Customization and automation solutions