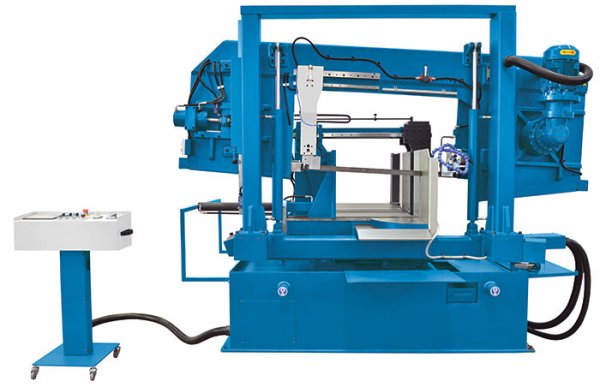

ABS 540 S NC

The ABS S NC is a high-performance production band saw with a dual column design. The material is fed via a controlled servo motor with ball screw drive and measuring system with a positioning and repeat accuracy of +/- 0.1 mm (0.0039 in). The Omron touchscreen controller can store up to 30 programs with 50 steps each. For additional flexibility, this series also offers hydraulic bundle clamping as an option. The manually set miter angle can be read on a digital display. The workpiece is clamped hydraulically.

- Double column design with linear guide for max. cutting precision

- Miter cutting with hydraulic angle clamping and digital display

- Omron touchscreen NC controller for fast program set-up

- Material servo-feeding for high precision

- 0.1 mm (0.0039 in.)

- automatic stroke height adjustment with optical sensor

- hydraulic top vise for bundle cutting